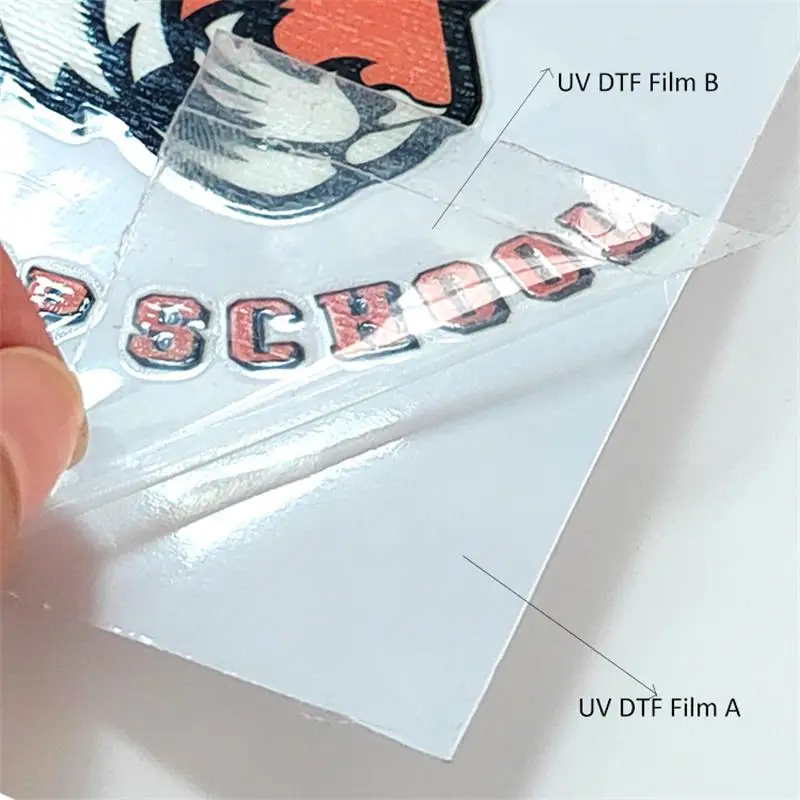

UV DTF printing is a new type of crystal label printing method. This technology requires A film (printing film), B film (transfer film), white UV DTF ink, UV vanish, etc.

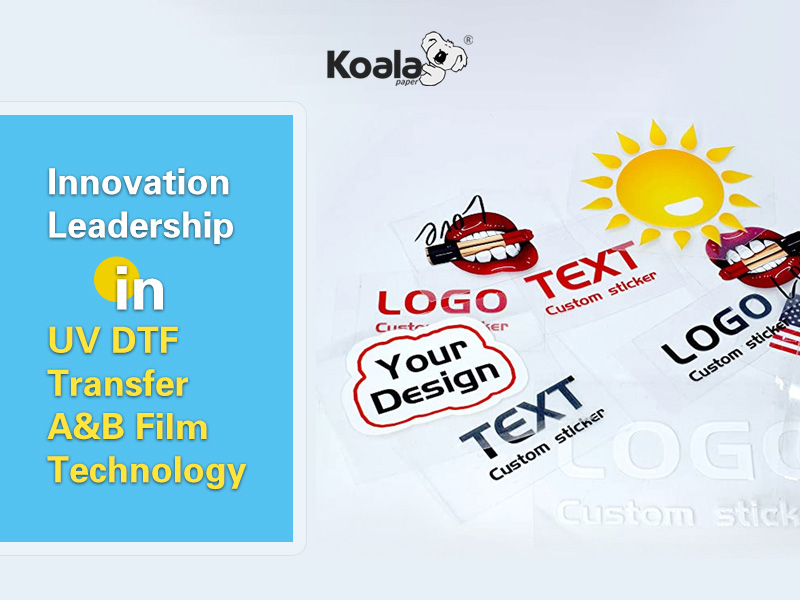

Introduction to UV DTF Printing Technology

● Working Principles

UV DTF printing is a new type of crystal label printing method. This technology requires A film (printing film), B film (transfer film), white UV DTF ink, UV vanish, etc. The A film is the printing film, which comes with adhesive. The adhesive layer also serves as the ink-absorbing layer. After printing, laminate it with film B. The B film is the transfer film, playing a role in protecting and transferring the printed design. The process involves printing the pattern on A film (printing film) first and then laminate it with B film (transfer film). This technology allows the printed design to be transferred to the surface of an object. The appearance has a three dimensional quality similar to crystal, hence the name crystal sticker. UV DTF stickers can be applied to many surfaces.

● Application Scenarios

UV DTF Transfer A & B Film can be widely applied to the surfaces of various hard materials, allowing patterns to be quickly transferred onto materials such as glass products, leather, wood products, metal, acrylic, paper packaging, and more. Koala Paper’s UV A&B films are most commonly used in the decoration and personalization of various consumer products and retail items. Popular application areas include mobile phone cases, laptop skins, water bottles, personalized gifts and promotional merchandise. The films allow for photo-quality images and vibrant colors to be printed quickly and applied to curved and irregular surfaces. They are also used for signage and way finding where a glossy, self-adhesive solution is required.

Koala Paper UV A&B Film Products

● Key Technical Specifications

Technical specifications are an important reflection of a product’s quality and performance. For Koala Paper, excellent technical metrics are key to gaining customer trust. It is understood that Koala Paper places a strong emphasis on controlling key technical specifications in their research and development of UV films.

For example, in selecting the film base, Koala Paper chooses to use stretched polymer as the substrate. This type of base has an ultra-flat, smooth surface conducive to sharp, clear print details. Additionally, Koala Paper performs precise thickness control. In theory, thickness impacts print effects and thin film structural strength, an important factor influencing the applicable scope. Koala Paper believes finely controlling thickness allows products to select the ideal film material for their intended application scenario.

In terms of adhesion, Koala Paper selects a solvent-free, high bond strength adhesive formula. Compared to solvent-based adhesives, it offers not only strong adhesion but also environmental friendliness. More importantly, the adhesive can reliably transfer printed patterns to various substrates without damage. The films are also optimized for light, weather, and climate durability.

● Product Advantages

Key advantages of Koala Paper’s UV A&B films include their suitability for small-run printing applications. Setup is fast and tools/dies are not required, lowering upfront costs. Digital printing enables on-demand customization. The films transfer cleanly without ghosting or release issues onto smooth and textured surfaces alike.

Their pressure-sensitive adhesive provides a strong yet removable bond for applications such as rental signage. Protection and decoration can be applied quickly without heat presses or complicated techniques. Combined with seamless compatibility across major printer brands, these films deliver proven innovation for next-level interior/exterior decoration and industrial marking.

Technical Support Services

As the leading manufacturer of UV DTF films, Koala Paper understands customers need comprehensive guidance to fully leverage their product innovations. With this in mind, the company provides expert technical support services to help optimize applications and maximize value.

● Consulting Services

Koala Paper’s professional consulting team offers personalized recommendations and best practices for integrating UV DTF films into specific manufacturing workflows and design needs. During initial setup, consultants analyze a customer’s printer, substrates, production volumes and goals to recommend the most suitable film types, ink sets, operating procedures and finishing techniques.

On-site evaluations are available to diagnose printability issues, assess current efficiencies and identify areas for improvement. Consultants work closely with customers to develop custom print profiles and testing parameters tailored to their applications and quality standards. For complex projects, video or remote assistance is provided for real-time troubleshooting.

● Customization Services

While Koala Paper’s product portfolio covers most standard decorative labeling and signage needs, the company understands some customers require highly customized solutions. The R&D and customization team support these needs through specialized film development projects.

Larger and more specialized customization projects may include film surface and chemistry modifications. Close collaboration ensures film properties andprinter/applicator compatibility. Comprehensive testing validates performance meets or exceeds customers’ durability, environmental and regulatory requirements.

By providing advanced technical support and customization options, Koala Paper delivers the industry’s most versatile UV DTF solutions and empowers customers with expert guidance throughout the product life cycle. This holistic and customizable approach underscores the company’s commitment to innovation leadership.

Future Development Planning

While Koala Paper has achieved great success, the company remains committed to innovation and driving the industry forward. They have ambitious R&D initiatives aimed at continual enhancement of UV DTF technology and new frontiers for applications. Koala Paper is committed to research and development to expand application of UV DTF films in emerging printing technologies and new material substrates.

To maximize productivity, Koala Paper aims to integrate AI-enabled process automation into film cutting, slitting and packaging lines. Real-time production data and predictive maintenance algorithms increase equipment uptime.

Connected devices and cloud-based platform integration empower customization and on-demand manufacturing. Through ambitious development goals, Koala Paper drives the UV DTF industry to new heights. Their road map establishes the innovation leadership, technology expertise and collaborative spirit needed to realize the full future potential of this rapidly evolving technology.