Table of Contents

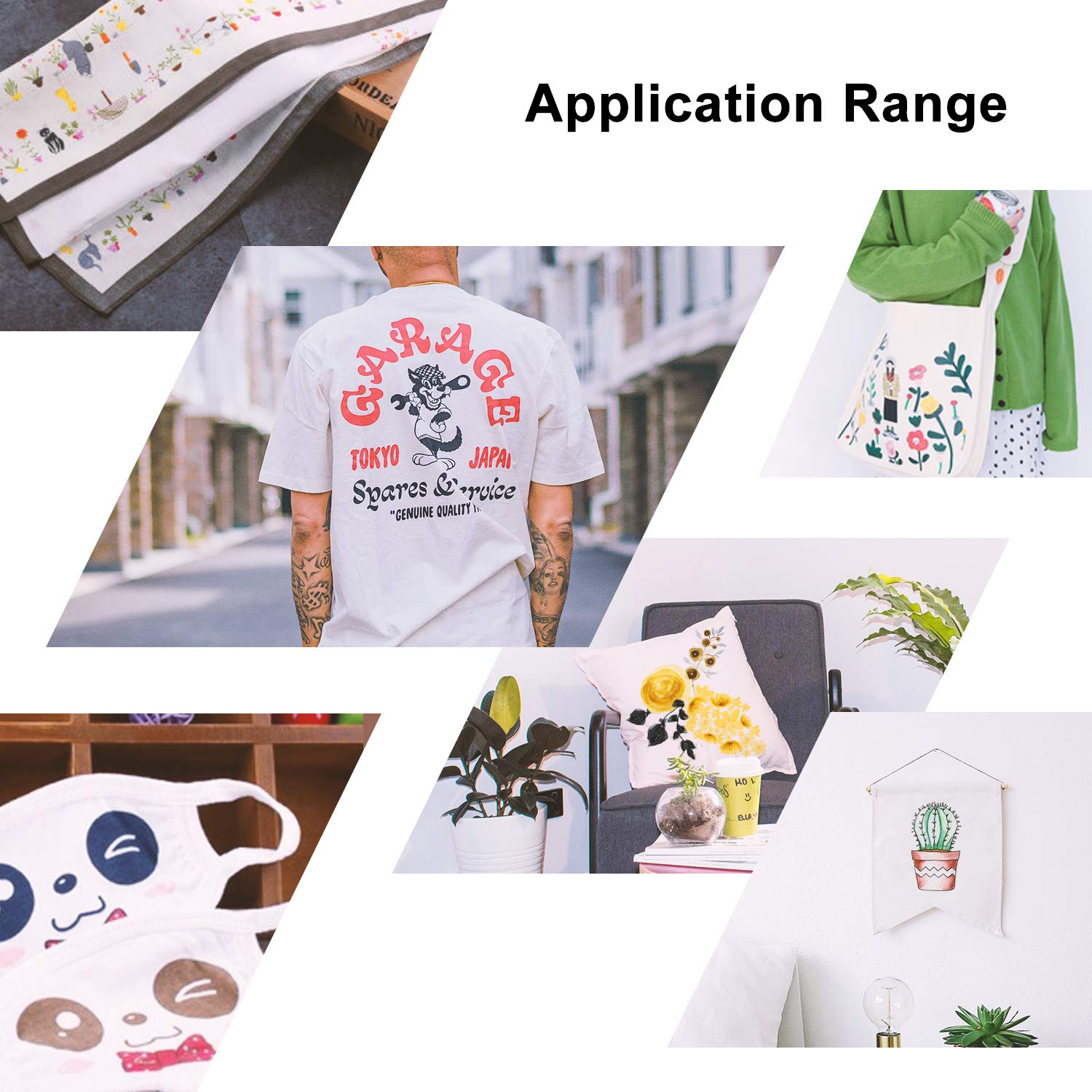

ToggleIntroduction: Why Application Scenarios are Crucial for Heat Transfer Paper Traders/Distributors/Wholesalers

For wholesalers purchasing in large quantities, choosing heat transfer paper is no longer just about price. By 2026, experienced buyers will be paying more attention to application compatibility, production stability, and factory after-sales service.

Unlike individual users, professional buyers must evaluate the following factors:

- Which type of inkjet T-shirt transfer paper is suitable for different business models?

- How do different sizes, coatings, and ink compatibility affect production efficiency?

- Can the transfer paper factory provide long-term bulk supply, customized specifications, and consistent product quality?

As a manufacturer with over 20 years of experience in sublimation/transfer paper, we focus on controlling paper stability and developing T-shirt transfer papers suitable for different application scenarios, going beyond just product descriptions. This article will explain how different heat transfer paper application scenarios meet diverse business purchasing needs.

Garment Printing Factory (Small to Medium-Sized Production Line)

Main Requirements:

- Stable printing quality

- High wash fastness

- Easy operation

- Suitable for cotton and blended fabrics

Recommended Solution:

- T-shirt inkjet heat transfer paper

- Light and dark fabric transfer paper

- Standard A3/A4 size or custom roll format

Why choose heat transfer paper for shirts?

For garment factories producing the following products:

- Custom T-shirts

- Event uniforms

- Workwear branding

Fabric heat transfer paper offers the following advantages:

- Short setup time

- Low technical barrier

- Fast order switching

Unlike DTF or screen printing, heat transfer paper is ideal for small batch production and multiple designs, reducing production time and waste.

Factory Advantages:

As a transfer paper factory, we offer:

- Consistent coating thickness

- Controlled adhesive release

- Batch-to-batch color stability

Print-on-Demand (POD) Platforms and E-commerce Sellers

Key Requirements

- Low Minimum Order Quantity (MOQ)

- Fast Order Processing

- Wide Fabric Compatibility

- Clean Peel-off Effect and Good Repeatability

Recommended Solutions

- Inkjet heat transfer paper for light fabrics

- Soft-feel heat transfer paper for dark fabrics

- Roll packaging for automated production

POD Specific Application Scenarios

POD sellers typically handle:

- Personalized text

- Custom photos

- Seasonal promotional campaigns

Advantages of T-shirt iron-on transfer paper:

- Production within the same day

- No pre-treatment required

- No expensive equipment needed

Compared to sublimation printing (limited by fabric type) or DTF (higher setup costs), heat transfer paper remains one of the most flexible POD solutions.

Factory Support is Crucial

We provide the following support:

- OEM packaging for POD brands

- Stable bulk supply for peak seasons

- Custom coatings for different POD printer models

Promotional Gifts and Corporate Branding Product Manufacturers

Typical Requirements

- Branded T-shirts

- Tote Bags

- Canvas Aprons

- Event Giveaways

Recommended Solution

- Dark Heat Transfer Paper

- High Opacity Coating

- Strong Adhesive

Why choose dark heat transfer paper?

Promotional orders require:

- Accurate logo colors

- Strong adhesion

- Cost control

Heat transfer paper for t-shirts ensures:

- Sharp logo edges

- High color density

- Lower unit cost for medium-volume orders

- Factory-level consistency

Our paper's coating system ensures:

- Even coverage

- Stable peeling performance

- High wash resistance (25-40 washes)

Heat Transfer Paper Wholesalers and Importers

Typical Requirements:

- Multiple SKUs

- Reliable factory supply

- Custom sizes and packaging

- Competitive FOB pricing

Application Scenarios:

Distributors serve:

- Local printing shops

- Schools

- Small businesses

- DIY market

They require inkjet heat transfer paper with the following characteristics:

- Easy to understand

- Suitable for beginners

- Compatible with mainstream printers

- Strong factory capabilities

We offer:

- A4/A3 paper sheets

- Heat transfer paper rolls

- Custom core sizes

- Private label and neutral packaging

This enables our distributors to:

- Build brand image

- Reduce returns

- Maintain consistent product quality

Schools, Training, and Educational Institutions

Key Requirements

- Safe materials

- Easy to use

- Low failure rate

Application Scenarios

Used for:

- Art classes

- DIY workshops

- Student projects

Heat transfer paper is favored because of:

- Low equipment requirements

- Clear visual results

- Minimal contact with chemicals

Factory Compliance

We ensure:

- RoHS compliant raw materials

- Stable coating adhesion

- Clear safety instructions

Custom Sportswear and Team Uniforms

Requirements

- Stretchability

- Washability

- Clear Numbers and Names

Recommended Solution

- Stretchable Heat Transfer Paper

- Medium Pressure Application

- Suitable for Cotton-Polyester Blends

Why choose iron-on transfer paper for inkjet printers?

Suitable for:

- Local Sports Teams

- Amateur Leagues

- Training Apparel

T-shirt iron-on transfer paper allows for quick personalization without a complete production line.

Factory Optimization

Our factory optimizes the following aspects:

- Elastic Polymer Formulation

- Crack-Resistant Coating

- Balanced Adhesive Strength

Production of Seasonal and Short-Term Promotional Products

Application Scenarios

Suitable for:

- Holiday promotions

- Limited edition products

- Influencer merchandise

Why iron-on shirt transfer paper is the ideal choice:

- No plate making required

- Low inventory risk

- Short delivery time

For individual sellers who need to cope with fluctuating demand, heat transfer paper offers unparalleled flexibility.

Comparative analysis insights for traders/wholesalers

| Solution | Best For | Limitations |

| Heat Transfer Paper | Short runs, cotton fabrics, flexibility | Film feel if misapplied |

| DTF | Mass production | Higher setup cost |

| Sublimation | Polyester & light fabrics | Fabric limitation |

| Screen Printing | Large volumes | Setup time & waste |

This comparison explains why heat transfer paper for shirts remains a strategic product for diversified traders/wholesalers.

Why Factory Background is More Important Than Brand Name

Wholesalers should prioritize:

- Coating consistency

- Production scale

- Technical support

- Long-term supply stability

Our transfer paper manufacturer’s strengths:

- Dedicated coating production lines

- Strict quality control for every batch

- Extensive OEM and ODM experience

- Stable export supply

By working directly with heat transfer paper factory, distributors can reduce:

- Supply chain risks

- Quality fluctuations

- Communication costs

Conclusion: Choose the right application solution, not just the product itself

A large batch of photographic paper is about to be shipped to destinations around the world.For professional buyers, the value of heat transfer paper lies in application suitability, not marketing hype.

Understanding:

- Your production model

- Your customer base

- Your sales structure

...will help you choose the right type, size, and coating of heat transfer paper.

As a factory-oriented supplier, We focus on actual production performance, long-term cooperation, and customized solutions—not just selling inkjet transfer paper.