Table of Contents

ToggleIntroduction: Why This Comparison Is Crucial

In recent years, the demand for custom stickers, labels, and personalized designs has exploded across various industries—from brand promotion and retail to home decor and gift packaging, the applications are incredibly diverse. Among the many sticker production solutions available today, UV A/B film and vinyl stickers paper are two of the most common choices.

At first glance, they seem to have overlapping functions: both can transfer colorful designs onto various fabrics and hard surfaces. However, they differ fundamentally in their working principles, durability, application process, substrate compatibility, and cost.

As a professional UV transfer film label manufacturer, we frequently receive the same question from wholesalers and distributors:

“Should my business choose UV transfer film or traditional vinyl stickers paper?”

This article will provide a comprehensive comparative analysis to help you clearly understand which solution is best suited for your application scenarios, production scale, and quality requirements, and will also look ahead to future trends.

What is UV DTF Film (Crystal Label)?

UV DTF film is a two-layer transfer system designed for applications that require no heating, no film removal, and only pressure application.

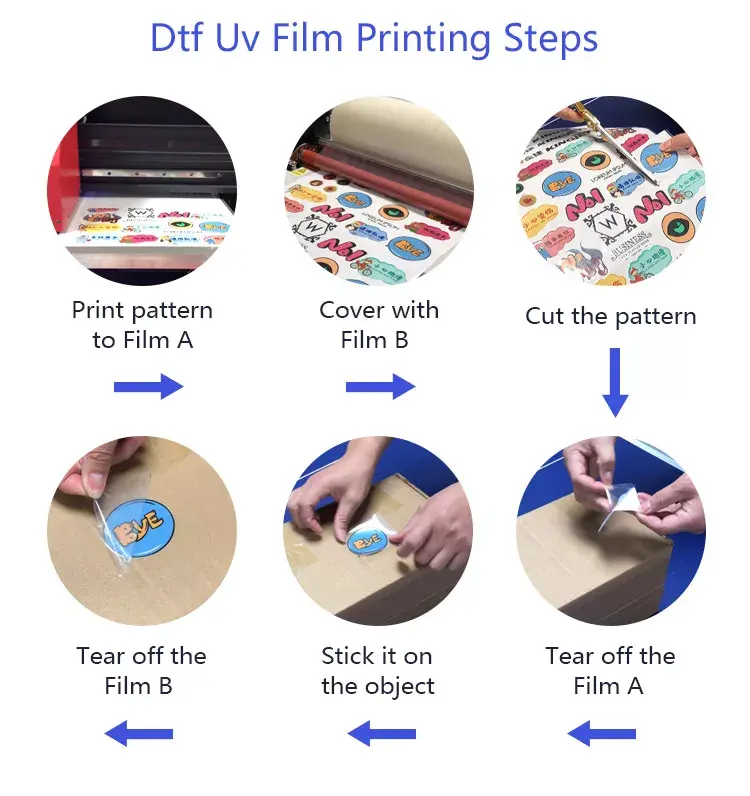

How it Works

A Film (Printing Film)

The pattern is printed using a UV printer. The UV ink instantly cures, forming a flexible and durable ink layer.

B Film (Transfer Film)

The B film is applied over the printed A film and coated with a specially formulated pressure-sensitive adhesive.

After peeling and applying pressure, the pattern is directly transferred to the substrate surface.

Main Features

- No cutting or film removal required

- No heat press machine needed

- Strong adhesion on hard, smooth surfaces

- High color saturation and 3D texture effect

- Excellent water resistance, scratch resistance, and chemical resistance

UV DTF film has become the ideal solution for high-end stickers applied to glass, metal, plastic, ceramic, wood, and coated hard surfaces.

What are Vinyl Stickers?

Vinyl stickers are typically made from PVC self-adhesive vinyl substrate material and printed using eco-solvent inks, solvent inks, latex inks, or UV inks. After printing, they are cut into shape using a plotter.

How it Works

- Print the pattern on the self-adhesive vinyl material

- Lamination (optional)

- Cut the pattern

- Remove excess material

- Apply transfer tape

- Transfer to the surface

Main Features

- Flexible and easily available

- Suitable for flat or slightly curved surfaces

- Suitable for simple patterns, cost-effective

- Requires cutting and film removal

- Adhesion varies depending on the quality of the vinyl material

However, vinyl stickers remain a widely used and excellent choice for temporary signage, packaging labels, and promotional purposes.

UV DTF A/B Film vs Vinyl Stickers: Full Comparison

Application Process

| Aspect | UV DTF A/B Film | Vinyl Stickers |

| Cutting Required | ❌ No | ✅ Yes |

| Weeding Required | ❌ No | ✅ Yes |

| Heat Press | ❌ No | ❌ No |

| Application Method | Pressure transfer | Adhesive sticking |

| Skill Requirement | Low | Medium–High |

Winner: UV Film

For efficiency, ease of use, and reduced labor cost, UV Film clearly outperforms stickers vinyl paper.

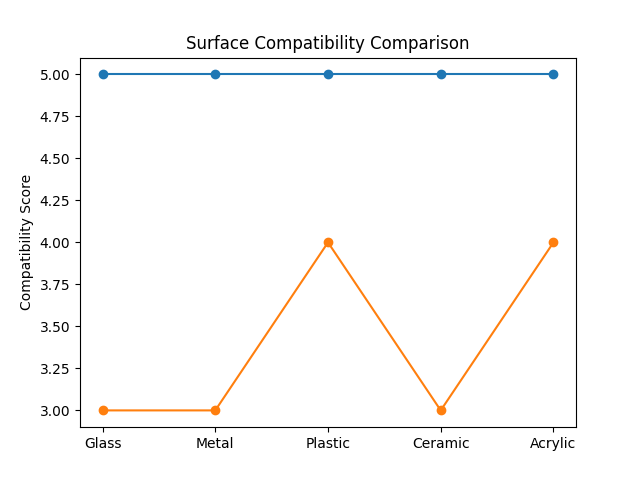

Surface Compatibility

| Surface Type | UV DTF A/B Film | Vinyl Stickers |

| Glass | ✅ Excellent | ⚠️ Limited |

| Metal | ✅ Excellent | ⚠️ Peeling risk |

| Plastic | ✅ Excellent | ✅ Good |

| Ceramic | ✅ Excellent | ⚠️ Limited |

| Wood (Coated) | ✅ Good | ⚠️ Limited |

| Fabric | ❌ Not suitable | ⚠️ Special vinyl needed |

Winner: UV A/B Film

UV Crystal Film offers far broader material compatibility, especially on non-porous and hard surfaces.

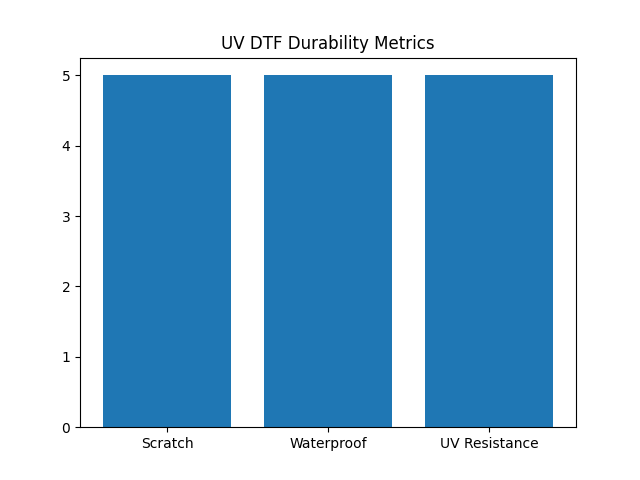

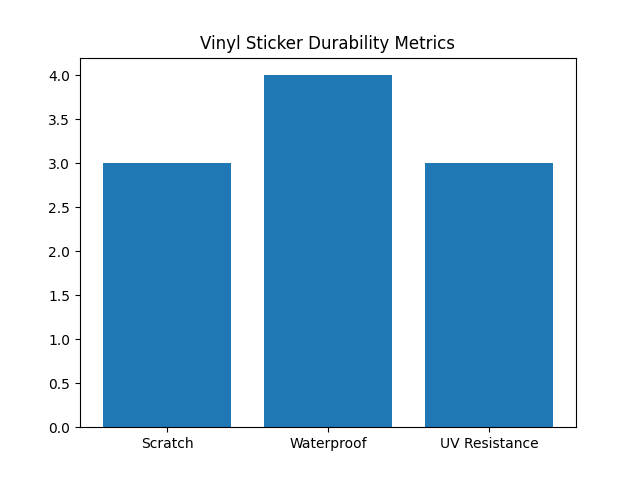

Durability & Longevity

| Performance Factor | UV DTF A/B Film | Vinyl Stickers |

| Scratch Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Waterproof | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| UV Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Edge Lifting | Rare | Common |

| Outdoor Lifespan | 3–5 years | 1–3 years |

Winner: UV Film For Stickers

Thanks to UV-cured ink and industrial-grade adhesive, UV Sticker Labels transfers behave more like permanent surface coatings than vinyl stickers paper.

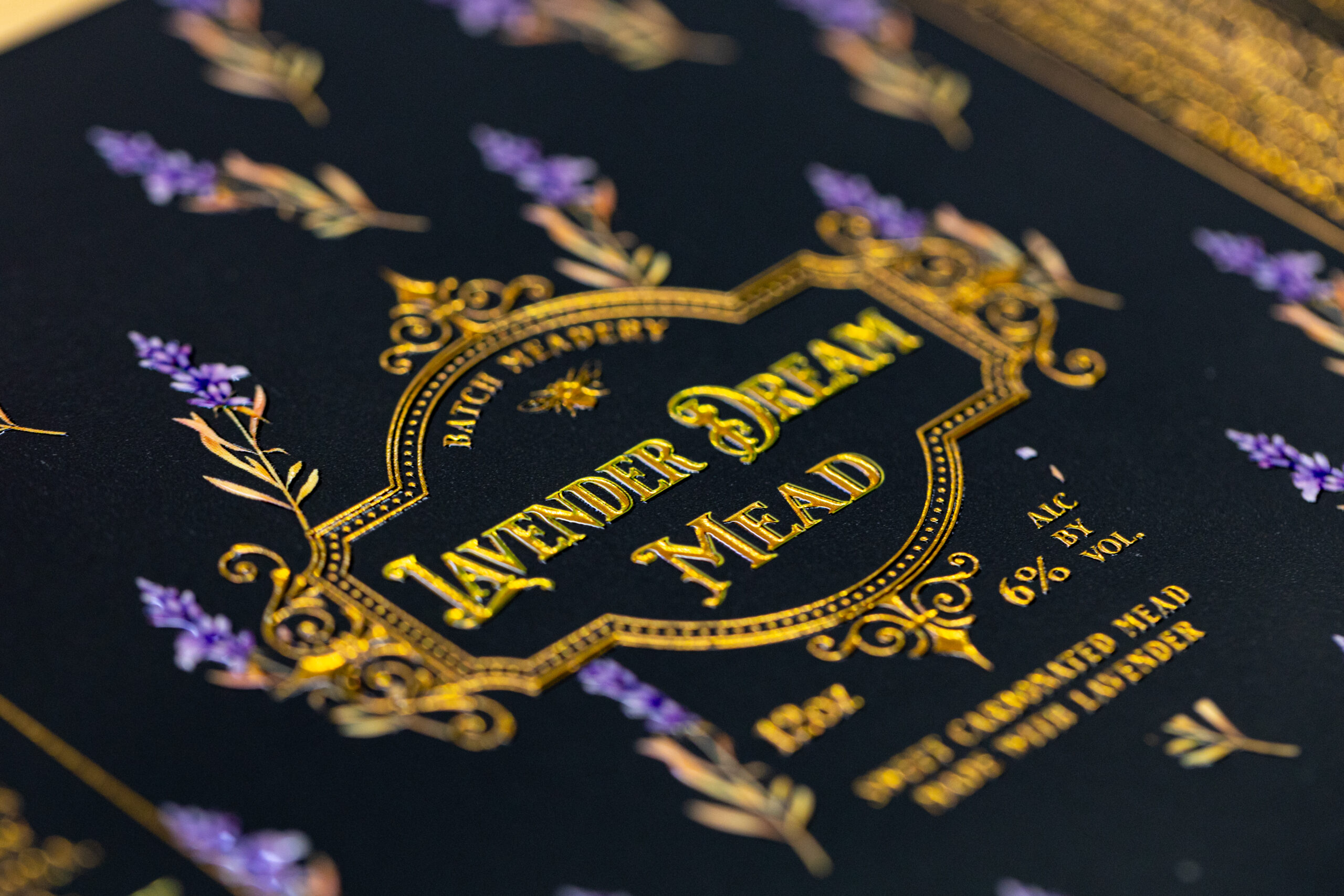

Visual Appearance & Texture

| Aspect | UV DTF A/B Film | Vinyl Stickers |

| Color Saturation | Very high | Medium–High |

| White Ink Support | ✅ Yes | ⚠️ Limited |

| Texture | Slight raised / 3D | Flat |

| Edge Visibility | Invisible | Visible |

Winner: UV Sticker Label Film

UV dtf printing film delivers a premium, label-free look, making it ideal for luxury branding and personalized products.

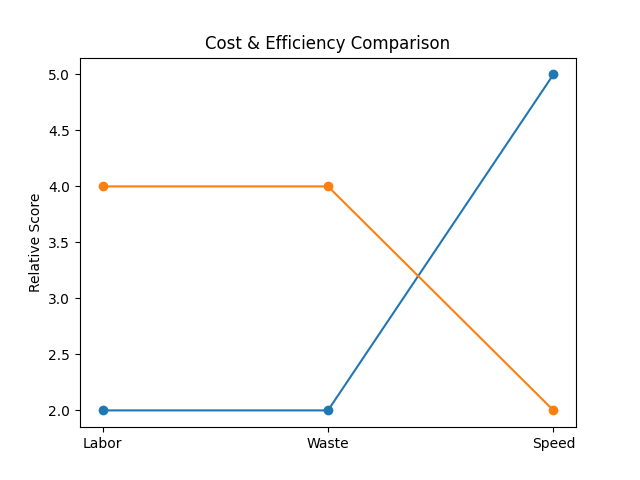

Production Efficiency & Cost

| Factor | UV DTF A/B Film | Vinyl Stickers |

| Setup Time | Low | High |

| Labor Cost | Low | High |

| Material Waste | Minimal | High (weeding) |

| Scalability | Excellent | Moderate |

Winner: UV A/B Film

While vinyl stickers may appear cheaper per sheet, UV Printing Film is more cost-effective in real production, especially for small batches and complex designs.

Why Vinyl Stickers Still Hold Value

Based on experience in the personalized customization industry, no single solution is perfect. The continued importance of vinyl sticker paper isn't because it's inherently better than newer solutions like UV DTF film, but rather because the choice depends on the specific application and production needs.

Wholesalers/distributors with experience in various printing processes understand that choosing the right technology often comes down to suitability, not simply opting for the newest sticker solution.

Industry Experience: The Reliable Performance of Vinyl Stickers

In real-world production environments—especially in small printing shops, distributors, and packaging suppliers—vinyl stickers remain widely used for applications with three common characteristics:

- Limited lifespan

- Low design complexity

- Strict cost control

These situations frequently occur in short-term marketing, packaging, and signage projects, where the limitations of vinyl stickers don't significantly impact the outcome.

Temporary Marketing Promotions

For trade shows, seasonal retail events, and promotional activities, vinyl stickers remain a practical solution because their lifespan is inherently short.

In these scenarios:

- Stickers are typically removed within a few weeks.

- Suboptimal color results are rarely a problem.

From a cost perspective, using a highly durable UV film transfer system is not cost-effective. Vinyl stickers offer limited color display at a lower cost, which aligns perfectly with the short-term marketing cycles common in the retail and events industries.

Efficiency Advantages for Simple, High-Volume Text Designs

In production environments consisting of:

- Text

- Single-color logos

- Large, simple shapes

The vinyl cutting process remains efficient and controllable. Many manufacturers and printing service providers have years of experience producing vinyl stickers.

For high-volume orders, vinyl stickers still offer the following advantages:

- Stable production

- Familiar quality control standards

- Scalable cost-effectiveness

This explains why vinyl stickers remain the preferred choice for low-cost, high-volume orders.

Packaging Applications

In the packaging supply chain, the evaluation criteria for labels go beyond durability; the key is the value proposition and its suitability for the packaging itself.

For single-use packaging—such as shipping boxes or paper retail packaging—the label's lifespan is short. In these cases, the focus is on meeting basic functionality rather than complex designs. Vinyl sticker paper meets the following basic requirements:

- Reliable adhesion to paper and coated paper

- Sufficient print clarity

This solution aligns with purchasing preferences in the logistics and retail distribution sectors.

Price limitations are a concern for wholesalers

From a B2B procurement perspective, price is often the biggest factor influencing decisions.

Vinyl stickers remain the preferred choice in the following situations:

- Projects are in the experimental or exploratory phase

- Products belong to a low-margin category

- Buyers prioritize unit price over long-term durability

In these cases, vinyl stickers allow businesses to meet short-term custom sticker needs without incurring higher costs.

Expert Opinion: Different sticker options depend on the specific application scenario

From a professional manufacturer and application perspective, vinyl stickers remain significant, not because they are superior, but because they are sufficiently suitable for specific scenarios.

With sticker development trends:

- Multi-surface compatibility

- Reduced manual labor

- Higher color demands

UV film is becoming increasingly popular, suitable for a wider range of applications than vinyl sticker paper.

However, experienced professionals recognize that the best solution is suitability, not imposing a single solution on all scenarios.

Conclusion based on trust

Vinyl stickers and UV transfer film are not competing with each other; they are solutions designed for different scenarios.

- Vinyl stickers effectively serve temporary, cost-sensitive, and simple applications.

- UV film excels in situations requiring durability, efficiency, and surface versatility.

When is UV Transfer Film the Better Choice?

UV film, with its superior visual quality, durability, and versatility, has become the preferred solution for modern custom sticker and label printing. For those seeking high-end custom results and fast delivery, UV DTF printing film offers a cost-effective solution.

Let's take a closer look at why UV film is the preferred choice for high-value applications across numerous industries.

Exceptional Color Results for High-End Products

One of the standout features of UV DTF film is its exceptional visual quality, making it the preferred choice for custom products. Whether you're creating personalized gifts, building a luxury brand image, or customizing promotional materials, UV film delivers crisp, vibrant, and color-accurate images that vinyl stickers simply can't match.

Advantages of UV DTF:

- True Color Reproduction: UV DTF uses high-quality UV inks that penetrate deep into the surface, ensuring vibrant colors that last.

- Realistic Effects: Perfectly renders detailed designs, including photographs, gradients, and complex artwork.

- Smooth Surface: No visible streaks or pixelation, ideal for products requiring high-definition detail.

For example, in luxury goods or personalized gifts, the high-quality output of UV Printing Film can significantly enhance customer appeal.

Long-Lasting Durability for a Lasting Impression

Unlike traditional transfer methods, UV DTF film offers exceptional durability. The UV-cured inks form a strong bond with the substrate, creating a tough, scratch-resistant, and waterproof surface.

This product is particularly suitable for:

- Outdoor applications

- Custom phone cases, mugs, and T-shirts

- Products subject to wear and tear, such as sportswear or promotional items

UV film can withstand harsh environments—from UV rays to moisture and extreme conditions—making it the best choice for products that require frequent use and long-lasting appearance.

No Cutting or Weeding Required – Fast and Efficient

Another key advantage of UV film for labels is the elimination of cutting and weeding, steps that are time-consuming in traditional vinyl sticker production or heat transfer printing. With UV film, the image is printed directly onto the film, eliminating the need for any post-processing before transferring to the target surface.

Importance:

- Increased Production: Faster production speeds mean more products can be printed in less time. Reduced labor costs: No cutting or weeding is required, allowing for automated production and thus lowering labor costs.

- Consistency and accuracy: There's no need to worry about misalignment or errors during the weeding process, resulting in higher product consistency.

Therefore, UV DTF film is ideal for businesses that require fast turnaround times and high-volume production of sticker labels.

High-Value Customized Products

As personalization continues to drive the consumer market, UV film provides the perfect solution for high-value personalized products requiring image-grade quality. Personalized gifts, corporate branding materials, and customized promotional products are just a few of the many application areas that can benefit from the ability of UV DTF Printing technology to produce personalized products on a large scale.

Whether it's a single custom T-shirt or a bulk order of branded gifts, UV DTF technology delivers unique, high-value products that meet the demands of today's personalized product market.

Why it's suitable for high-value products:

- Superior Quality: UV printing technology offers excellent visual effects and durability.

- Scalability: High-precision patterns can be printed without minimum order quantities, allowing printing service companies to offer small-batch customization services.

Why do our UV DTF films stand out?

As a professional sticker label manufacturer, we always prioritize production stability when designing our UV DTF films:

- Optimized adhesive balance (B film has strong adhesion but is easy to peel off)

- Stable ink release from the A film

- High-resolution coating uniformity

- Consistent quality across large production batches

- Supports OEM and ODM customization

Our UV DTF films are trusted by customers in North America and Europe, meeting the diverse needs of both small studios and industrial users.

Final Verdict: UV DTF or Vinyl Stickers?

| If You Value… | Choose |

| Premium appearance | UV DTF A/B Film |

| Fast, easy production | UV DTF A/B Film |

| Multi-material application | UV DTF A/B Film |

| Lowest material cost | Vinyl Stickers |

| Temporary use | Vinyl Stickers |

UV DTF A/B Film is no longer an alternative—it is the upgrade.