Table of Contents

ToggleIntroduction: The Importance of UV DTF A/B Film in 2026 is Self-Evident

Manufacturer's Perspective | Supporting OEM and Wholesale | Global Supply

This article is published by Koala® Factory, a professional manufacturer of printing consumables (Film/Vinyl Label), specializing in UV DTF transfer film, digital printing consumables, and providing OEM sticker label and label facestock solutions for global trade/distributors. If you are considering purchasing UV Transfer A/B film for wholesale distribution, private label branding, or industrial applications, this guide is tailored for you.

In 2026, UV DTF A/B film has rapidly evolved from a niche labeling solution to a mainstream solution for hard surface decoration. Brands, printing companies, and global buyers are actively seeking alternatives to traditional heat transfer, UV flatbed printing, and traditional sublimation/DTF printing – especially solutions that reduce equipment costs, offer multi-scenario applications, and eliminate the need for heat pressing.

This guide takes the perspective of manufacturers and traders, combining production knowledge, application testing, and industry trends. This article will explain in detail how UV DTF film works, its advantages over other technologies, and how professional buyers should evaluate product quality in 2026.

What is UV Transfer A/B Film (Crystal Label)?

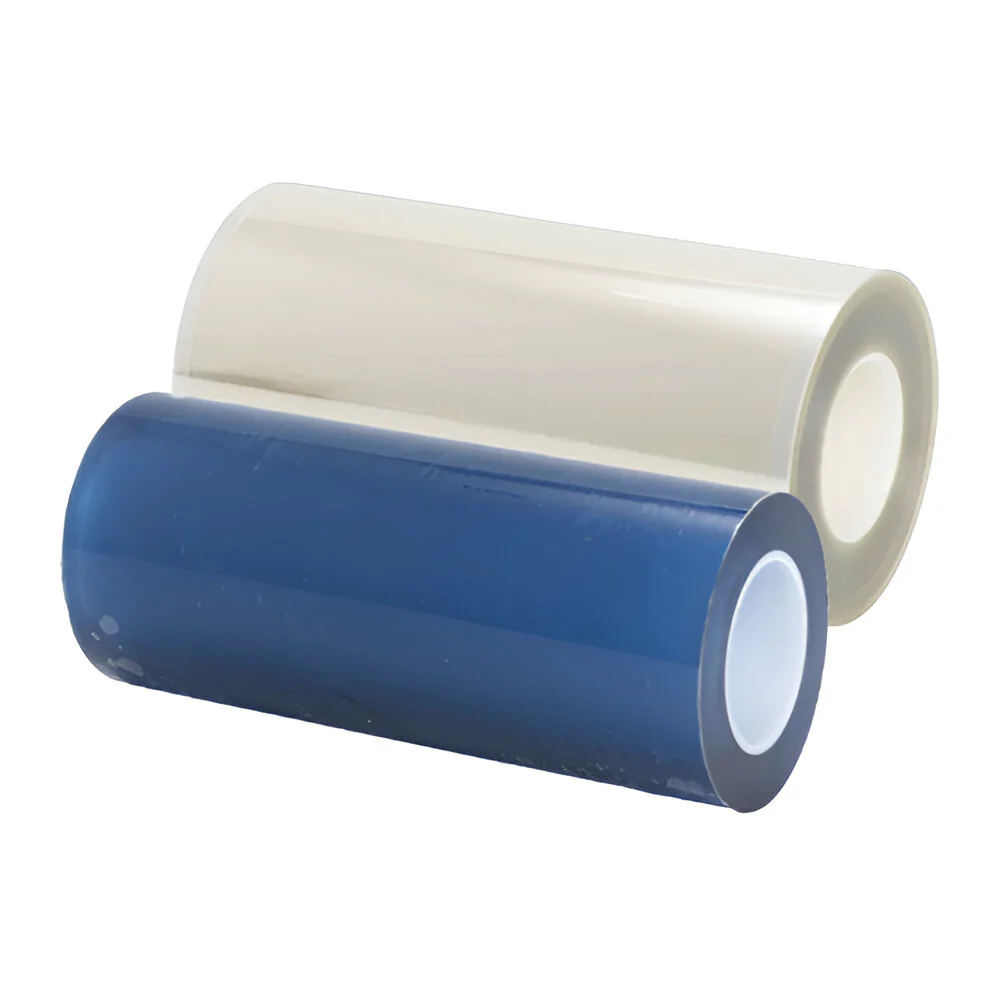

UV Transfer A/B film is a two-layer cold transfer system, also known as a crystal label, specifically designed for decorating hard, non-porous surfaces or fabrics without the need for heat. It consists of two parts:

- A film (Printing film):A carrier film used to hold the design, which is printed using UV-curing ink.

- B film (Adhesive film):A pressure-sensitive adhesive film used for lamination and transferring the printed image.

Basic steps: After UV printing and curing on the A film, the B film is laminated on top. The final design can then be transferred to substrates such as glass, metal, plastic, ceramics, acrylic, and coated wood without further heating or a heat press.

This fundamentally differentiates UV Transfer film from traditional DTF or sublimation printing systems that rely on heat press systems.

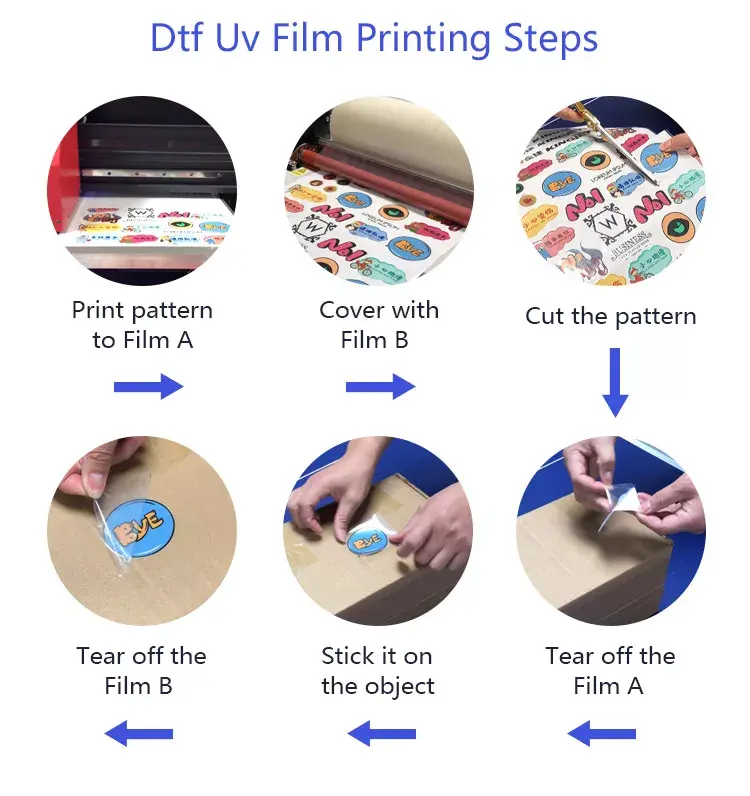

UV A/B Film Operating Principle: Step-by-Step Technical Process

Understanding the transfer process of UV film is crucial for our customers to evaluate quality and compatibility.

Step 1: UV Printing on Film A using a UV Printer

- UV ink is printed onto Film A in reverse order.

- White ink is typically used as the base layer.

- The UV ink layer is instantly cured using UV LED lights.

From a factory perspective, ink absorbency, film surface properties, and the consistency of the release coating determine whether the printed layer can be cleanly peeled off later.

Step 2: UV Curing

UV curing instantly solidifies the ink film. Unlike solvent-based or water-based inks, UV ink forms a polymer layer with excellent chemical resistance (resulting in a prominent texture).

Key curing parameters: - UV wavelength: 365–395 nm - Consistent curing energy - Ink film thickness control

Step 3: Cold Lamination with Film B

Film B has a specially formulated pressure-sensitive adhesive. Lamination is performed at room temperature using a laminator.

Typical lamination pressure: - 0.3–0.5 MPa

No heating is required, thus avoiding deformation of the substrate due to high-temperature hot pressing.

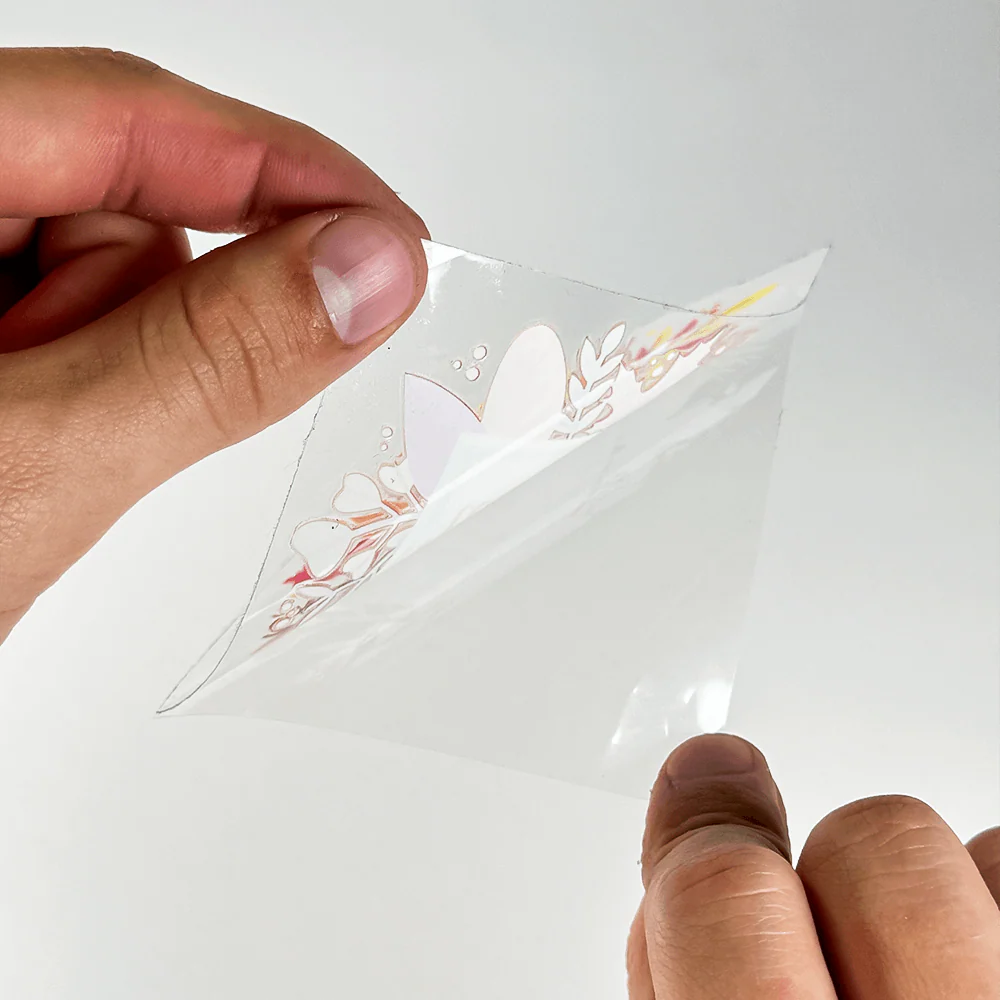

Step 4: Transfer to the Substrate

After peeling off Film A, the graphic (now attached to Film B) is directly applied to the surface of the substrate. Gentle pressure ensures adhesion.

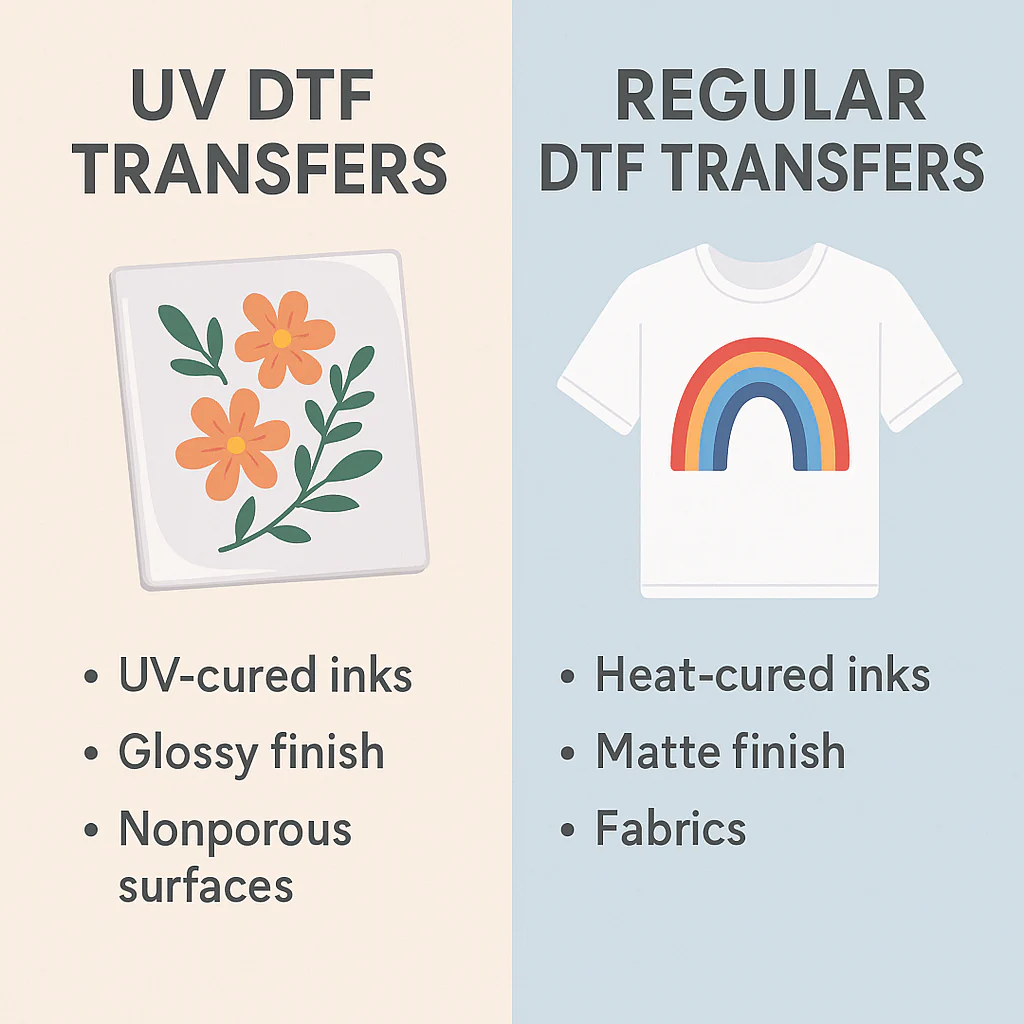

UV DTF vs Traditional DTF vs Sublimation vs UV Flatbed Printing

| Technology | Heat Required | Substrate Type | Equipment Cost | Flexibility |

| Sublimation Paper | Yes | Mainly textiles and hard surface | Low | Limited |

| Traditional DTF Film | Yes | Fabrics | Medium | Fabric-only |

| UV Flatbed Printing | No | Hard surfaces | Very High | Low mobility |

| UV DTF A/B Film | No | Hard surfaces | Medium | Very High |

UV transfer A/B film cleverly combines the advantages of UV flatbed printing quality and sticker-like flexibility, making it currently the optimal labeling solution.

Key Factors that Traders/Printers/Distributors Value Most in UV A/B Film

4.1 Adhesion Strength

Our label factory measures this through cross-hatch and peel tests on glass, stainless steel, PET, and acrylic materials.

4.2 Transparency and Optical Clarity

High-quality A film remains clear and transparent without haziness, which is crucial for transparent designs.

4.3 Durability and Chemical Resistance

UV transfer patterns are resistant to: - Water - Alcohol - Mild detergents

4.4 Peel Stability

A controlled peeling process ensures clean separation without edge lifting or ink tearing.

Typical Crystal Label Application Scenarios

👉 Looking for product specifications or wholesale prices?

Please visit our official product page: UV A/B Film

Our UV DTF film is designed for both large-scale production and small-batch customization, offering stable and reliable quality.

5.1 Drinkware and Promotional Items

Water bottles, glasses, stainless steel bottles – UV DTF technology enables small-batch customization without the need for molds.

5.2 Industrial Labels and Equipment Identification

UV Transfer film is widely used for control panels, appliance branding, and warning labels.

5.3 Home Decor and Retail Displays

Acrylic signs, decorative tiles, and branded fixtures can all benefit from this heat-free transfer technology.

Manufacturing Perspective: The Characteristics of Koala’s Professional UV A/B Film Factory

From the perspective of our professional label factory, the stability of UV label film is paramount. This is not just about whether the UV film is "usable," but more importantly, whether it can consistently and reliably transfer images across different brands of UV printers, UV inks, production environments, and batches.

The following are four core manufacturing factors that differentiate a professional UV transfer film factory from trading companies or small workshops.

6.1 Coating Uniformity and Thickness Control

UV A/B film relies on multiple functional coatings, including release layers, ink-absorbing layers, and adhesive layers. Even a slight deviation in coating thickness can lead to serious quality problems, such as uneven ink curing, poor release, or edge lifting.

At our label film factory, coating uniformity is controlled through:

- Precision slot die coating and gravure coating systems

- Real-time thickness monitoring during the production process

- Strict tolerance control across the entire width of the roll

Consistent coating thickness ensures:

- Stable adhesion of UV ink during printing

- Clean and complete image release during transfer

- No visible haze, streaks, or density variations in transparent designs

6.2 Adhesive Formulation Stability

The adhesive used in UV DTF B film is one of the most critical influencing factors. Unlike hot-melt adhesives, UV B film relies on pressure-sensitive adhesives, which must balance three complex technical requirements:

- Strong initial tack under cold pressure

- Long-term adhesion on hard, non-porous surfaces

- Controllable removal of the A film without damaging the ink

Our factory formulates and adjusts the adhesive formula ourselves, rather than purchasing generic adhesives. In our factory, the adhesive system:

- Is adjusted for different substrate types (glass, metal, plastic, acrylic)

- Is tested for temperature and humidity stability

- Is evaluated for aging performance to prevent yellowing or brittleness

This formulation stability is crucial for commercial buyers who require reliable transfer results in high-volume production.

6.3 Batch-to-Batch Consistency and Quality Control

Quality Control

For distributors, brands, and OEM customers, batch consistency is often a top priority. Inconsistent batches can lead to production downtime, customer complaints, and material waste. A professional UV DTF film factory implements the following measures:

- Raw material traceability system

- Standardized production formulas

- Incoming, in-process, and final inspection stages

At our factory, every batch of product undergoes the following tests:

- Adhesion test on standard substrates

- Peel strength measurement

- Compatibility testing with mainstream UV ink brands

This ensures that the UV film purchased today performs consistently with UV film purchased months later – a fundamental requirement for wholesale and long-term supply contracts.

6.4 Cleanroom Lamination and Production Environment Control

Dust, static electricity, and airborne particles are significant threats to the quality of UV printing films. Contamination during the lamination process can lead to pinholes, adhesion defects, or visible surface imperfections.

Professional label manufacturers perform lamination in a cleanroom or controlled environment to ensure:

- Temperature and humidity are strictly controlled

- Static electricity is minimized

- The film surface remains clean and free of contaminants

Our UV film factory utilizes a controlled lamination environment, guaranteeing smooth adhesion between the A and B films, ensuring perfect transfer results even for fine graphics.

6.5 Compatibility Testing with Different UV Ink Brands

Not all manufacturers' UV inks perform the same. Differences in viscosity, curing energy, and chemical composition can affect adhesion and peeling performance.

Our film/vinyl label factory doesn't optimize UV film for a single UV ink brand, but instead conducts compatibility testing with multiple brands, including:

- White ink coverage performance

- Flexibility of the cured ink

- Adhesion retention after transfer

This testing method allows our UV DTF film to be compatible with various UV printers used by customers worldwide.

Common Problems and How Manufacturers Solve Them

| Problem | Root Cause | Factory Solution |

| Poor adhesion | Low surface energy | Adhesive reformulation |

| Ink cracking | Over-curing | Ink layer optimization |

| Edge lifting | Uneven lamination | Release coating control |

How to Choose UV Transfer A/B Film (Buyer’s Checklist)

Our UV Film purchasing tips for buyers: When purchasing UV film for resale or large projects, be sure to request factory test data and batch consistency records.

When choosing a UV transfer A/B film supplier, professional buyers should evaluate the following points:

- Compatibility with your UV printer

- Stable adhesive performance under cold pressing

- Consistent release performance

- Provision of factory test data

- Support for OEM and width customization

UV DTF Film Industry Trends in 2026

- Increased demand for personalized customization without heating

- Growth in small-batch personalized customization businesses

- Expansion into the industrial labeling sector

UV A/B film is expected to become one of the fastest-growing segments in the digital printing and decoration market.

Conclusion: Partner with a Reliable UV Label Film Manufacturer

By 2026, UV A/B film will no longer be an experimental solution – it will be a mature and scalable technology widely adopted by brands, manufacturers, and professional printers worldwide.

By choosing a factory-backed supplier like us, buyers will benefit from:

- - Consistent batch quality

- - OEM and private label support

- - Application testing compliant with global standards

- - Long-term technical support

Interested in wholesale pricing or samples?

Contact our label factory today to discuss your UV A/B film needs.

Koalapaper Factory – Professional UV DTF Transfer A/B Film Manufacturer

OEM | ODM | Global Export | Stable Quality

UV DTF transfer A/B film represents a significant transformation in brand hard surface decoration methods. Combining the durability of UV ink with the flexibility of cold transfer, it provides manufacturers, distributors, and printing companies with a scalable and cost-effective solution for 2026 and beyond.

What is UV DTF Transfer A/B Film and how is it different from traditional DTF?

UV DTF Transfer A/B Film is a cold transfer system designed for hard surfaces. Unlike traditional DTF, which requires heat pressing and is mainly used for textiles, UV DTF uses UV-curable ink and pressure-sensitive adhesive to transfer graphics onto glass, metal, plastic, acrylic, and ceramic without heat.

What are A Film and B Film used for in UV DTF transfer?

The A Film is the printing carrier where UV ink is printed and cured, while the B Film contains the pressure-sensitive adhesive. After lamination, the B Film transfers the cured ink layer from the A Film onto the target surface, ensuring strong adhesion and clean release.

Does UV DTF Transfer A/B Film require heat or a heat press?

No. UV DTF Transfer A/B Film uses cold lamination and pressure-based adhesion. No heat press is required, which eliminates the risk of substrate deformation and expands application possibilities for heat-sensitive materials.

What types of surfaces are compatible with UV DTF Film?

UV DTF films are compatible with most smooth, non-porous surfaces, including glass, stainless steel, aluminum, PET, acrylic, coated wood, and ceramic. Surface cleanliness and surface energy still play a role in final adhesion performance.

How durable are UV DTF transfers in real-world use?

When produced with high-quality film and proper UV curing, UV DTF transfers offer excellent resistance to water, mild chemicals, and daily handling. Durability depends on adhesive formulation, ink compatibility, and application conditions.

Is UV DTF Transfer Film compatible with all UV printers and inks?

Most professional UV DTF films are compatible with mainstream UV printers and inks, but performance may vary depending on ink chemistry and curing energy. Reliable manufacturers conduct cross-brand UV ink compatibility testing to ensure stable results.

What are common quality issues with low-grade UV DTF films?

Common problems include poor adhesion, ink cracking, edge lifting, inconsistent release, and haze on transparent designs. These issues are often caused by unstable adhesive formulations, uneven coating thickness, or lack of batch quality control.

How should B2B buyers evaluate a UV DTF Film manufacturer?

Professional buyers should look for:

Stable batch-to-batch consistency

In-house coating and adhesive formulation

Cleanroom or controlled lamination environments

Factory testing data and technical support

OEM and customization capabilities

Can UV DTF Transfer A/B Film be customized for OEM or wholesale orders?

Yes. Professional factories like Koala support OEM and wholesale customization, including roll width, adhesive strength, release characteristics, packaging, and private labeling for distributors and brands.

Is UV DTF Transfer A/B Film suitable for large-scale production?

Yes. UV DTF is widely used in both small-batch customization and scalable production. With consistent materials and controlled processes, it supports repeatable results required for wholesale, promotional, and industrial labeling applications.