Table of Contents

ToggleWhy T-Shirt Transfer Paper is So Important and Promising in 2026

In 2026, driven by factors such as the rapid development of e-commerce, personalized customization and on-demand apparel printing services, and one-stop printing solutions, the demand for apparel customization is steadily and continuously growing across all regions of the world. According to data from Verified Market Research and Future Market Insights, the global digital textile printing and transfer paper industry is projected to grow at a compound annual growth rate of over 11% from 2024 to 2032, thanks to the booming on-demand printing business, brand promotion needs, sportswear customization, and the influencer effect of short video creators.

In this market, T-shirt transfer paper remains one of the most popular, easy-to-use, and cost-effective apparel printing technologies. Compared to more complex systems like DTF and DTG, transfer paper has lower entry costs, greater compatibility, and requires less equipment, making heat transfer paper for shirts a highly reliable option for small businesses, startups, print shops, schools, gift manufacturers, and DIY creators.

This guide will provide an in-depth and professional explanation of how inkjet heat transfer paper works, its types, advantages, limitations, practical production considerations, and its differences from sublimation printing and DTF printing technologies – aiming to help buyers, manufacturers, and traders make informed bulk purchasing decisions.

Sources:

https://www.verifiedmarketresearch.com/product/textile-transfer-paper-market/

https://www.futuremarketinsights.com/reports/digital-textile-printing-market

What is heat transfer paper for t-shirts? (Basic Concept)

Transfer paper for shirts is a specially coated printable medium with a heat-sensitive adhesive layer on its surface. The ink-absorbing coating carries the ink from a digital printer, and under the action of heat and pressure, the ink is transferred to the fabric. This is extremely important because it allows the printed design to be fixed and transferred to garments made of cotton, blends, and polyester fibers under controlled conditions. Unlike ordinary paper,heat transfer paper contains:

- Ink absorption layer

- Heat-sensitive adhesive film

- Protective base layer

When used with a heat press or a household iron, the adhesive layer of inkjet iron-on transfer paper melts and bonds the design to the textile fibers, creating durable, brightly colored printed garments.

Technical References:

How Fabric Transfer Paper for Shirts Works (Science and Practice)

From a technical perspective, the success of heat transfer depends on three main factors:

3.1 Coating and Ink Adhesion

Iron-on shirt transfer paper has a polymer film coating on its surface that bonds with the ink during printing. When heated, this film becomes viscous, allowing the ink and film to fuse onto various fabric surfaces under pressure.

Fabric transfer paper is designed to balance the following factors:

- Ink absorbency

- Adhesion

- Peel performance

Uneven or incorrect coating can lead to ink bleeding, poor adhesion, or uneven transfer results.

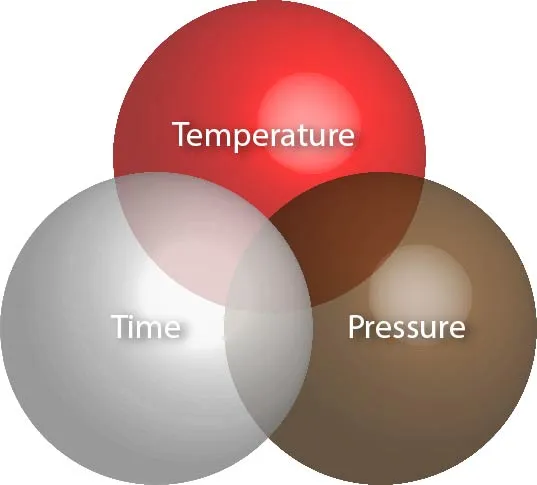

3.2 Temperature, Pressure, and Time

Temperature melts the adhesive layer, allowing the printed film to bond with the fabric. Most heat transfer applications require temperatures of 160-190°C, with specific time and pressure parameters depending on the type of paper and fabric. Incorrect settings of these variables can lead to transfer problems.

3.3 Fabric Interaction

Different types of fabrics have different bonding mechanisms:

Cotton/cotton blend fabrics usually bond through surface adhesion.

Polyester/synthetic fibers may require different formulations or even the use of sublimation paper (another type of transfer paper) for optimal results.

Technical Guides:

FESPA Heat Transfer Overview

https://www.fespa.com/en/news-media/features/heat-transfer-printing-explained

Stahls Heat Press Guide

https://www.stahls.com/heat-press-guide

Types of T-Shirt fabric heat transfer paper

Understanding the different types of shirt heat transfer paper is crucial for choosing the right transfer paper for your fabric.

4.1 Light Fabric Transfer Paper

This is the most common type used for white/light-colored garments. The coating on this transfer paper releases the image cleanly when heated, resulting in vibrant colors on light-colored substrates.

Best suited for:

✔ Standard cotton t-shirts

✔ Tote bags

✔ Light-colored promotional apparel

4.2 Dark Fabric Transfer Paper

This heat transfer paper is designed for printing vibrant, opaque images on dark fabrics. It typically includes a white base layer to prevent the dark fabric from affecting the final color presentation.

Best suited for:

✔ Black or dark-colored fashion t-shirts

✔ High-contrast designs

✔ Streetwear

4.3 Inkjet Heat Transfer Paper

Designed for inkjet printers. This paper can be used with pigment or dye inks and is one of the ideal choices for full-color designs.

Note: Not all inkjet printers can handle thicker transfer paper without adjusting the paper feed settings.

4.4 Laser T-shirt Transfer Paper

Used with laser printers, this paper is designed to handle the toner fusion process, producing crisp, durable, and vibrant graphics.

Best suited for:

✔ High-volume printing

✔ Designs with clean lines and primarily text-based designs

Comparison of T-shirt Heat Transfer Paper with Sublimation and Other Printing Technologies

Sometimes, many people confuse inkjet heat transfer paper with other garment printing technologies. Therefore, it's crucial to accurately distinguish between them:

5.1 Heat Transfer Paper vs. Sublimation Paper

Heat transfer paper uses an adhesive film to bond the image to the fabric. Sublimation transfer paper, on the other hand, converts the dye into a gas and embeds it into the polyester fibers.

- Heat transfer paper: Suitable for cotton and blended fabrics

- Sublimation: Best suited for polyester fibers and coated hard products

This difference results in fundamental differences in print quality and fabric compatibility.

5.2 Heat Transfer Paper vs. Screen Printing

Screen printing uses a screen and ink layers applied directly to the fabric. Heat transfer paper has a simpler setup process, but its washability may not be as good as screen printing.

5.3 Heat Transfer Paper vs. Direct-to-Film (DTF) Printing

DTF printing uses DTF PET film, hot melt adhesive powder, and a DTF printer/ink to produce flexible and washable prints. Heat transfer paper is less expensive, but its washability may not be as good as DTF printing, especially with frequent washing.

How to Use T-Shirt Transfer Paper

Whether you run a printing business or are working on DIY projects at home, mastering the techniques of using T-shirt heat transfer paper will ensure you produce vibrant, durable, and professional-looking designs.

6.1 What You Need

Before starting, prepare the following equipment:

- Inkjet or Laser Printer (match your paper type)

- Heat Transfer Paper (Light or Dark)

- Heat Press Machine or Iron

- Cutting Tools (scissors or vinyl cutter)

- T-shirt / Fabric Blank

- Parchment Paper or Teflon Sheet

- Flat, Stable Working Surface

6.2 Design & Print Preparation

Step 1: Create or Select Your Design

You can use:

- Photoshop

- Illustrator

- CorelDRAW

- Silhouette Studio

- Cricut

- Canva

Recommended Specs:

- High resolution 300 DPI

- RGB color mode

- Transparent background for light fabric transfer paper

Step 2: Mirror or Do Not Mirror?

- Light Transfer Paper → Mirror ON

- Dark Transfer Paper → NO MIRROR

This step is essential to avoid reversed prints.

Step 3: Printer Settings

Choose:

- Photo Quality

- Best Print Mode

- Paper Type = Photo / Special Media

For Ink Types:

- Dye Ink = Brighter but less wash-resistant

- Pigment Ink = Better durability & fade resistance

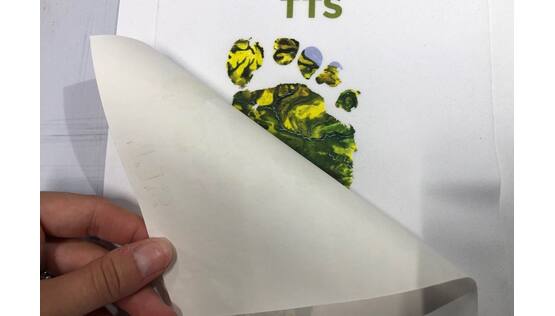

6.3 Cutting & Peeling

Depending on your workflow, choose:

✔ Kiss-Cut with Cutter

Better for:

- Complex logos

- Business customization

- Professional production

✔ Hand Cutting

Suitable for:

- Simple shapes

- DIY users

6.4 Heat Press Settings (Time, Temp, Pressure)

⚠ Settings may vary depending on the brand of inkjet transfer paper. The following are industry standard settings that have been tested:

⭐ Light Fabric Heat Transfer Paper

- Temperature: 180–190°C / 356–374°F

- Time: 20–30 seconds

- Pressure: Medium

Peeling Method: Peel while hot or warm (please check paper instructions)

⭐ Dark Fabric Heat Transfer Paper

- Temperature: 160–170°C / 320–338°F

- Time: 25–30 seconds

- Pressure: Medium to High

Peeling Method: Recommended to peel after cooling (please check paper instructions)

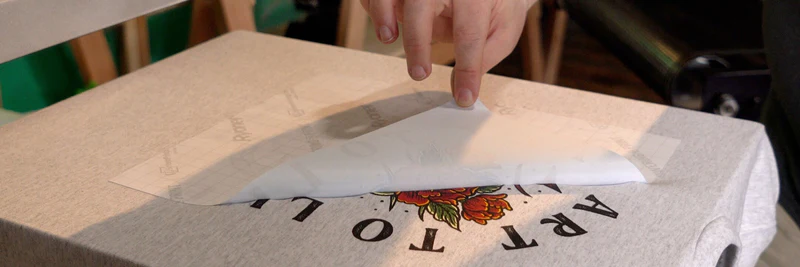

6.5 Pressing Process (Iron or Heat Press)

✔ Using a Heat Press

- Preheat the heat press.

- Pre-press the garment (2-3 seconds to remove moisture).

- Place the transfer paper.

- Cover with protective paper.

- Apply heat according to the settings.

- Carefully peel off the backing paper.

- Press again (optional, to enhance durability).

✔ Using a Household Iron

If you don't have a heat press, you can still successfully apply the transfer.

Important Tips:

- Use high heat.

- Turn off the steam function.

- Apply even pressure.

- Press in sections, do not slide the iron.

Ironing Settings:

- Cotton setting

- Iron for 3-5 minutes depending on the size of the design.

Market Demand & Business Value

In 2026, t shirt transfer paper remains essential because:

- ✔ Affordable production

- ✔ Flexible order volume

- ✔ Fast delivery

- ✔ Widely adopted in B2B garment decoration

Applications include:

- Custom apparel

- Promotional uniforms

- Corporate branding

- Ecommerce POD

Why High-Quality Transfer Paper Matters

High-quality t shirt transfer paper delivers:

- Better wash durability

- Bright color

- Softer hand fee

- Fewer prduction errors

Is t shirt transfer paper suitable for commercial production?

Yes. It is widely used in promotional apparel, retail customization, and enterprise branding.

How long does transfer paper last on clothing?

With quality paper and correct pressing, it lasts 30–50+ washes.

Can it work on cotton?

Yes. Unlike sublimation, transfer paper works perfectly on cotton.

Does it crack?

Only if poor paper or incorrect pressing is used.

Inkjet or Laser?

Both work, depending on the paper type selected.