Table of Contents

Toggle1.Introduction

As is well known, sublimation technology places stringent requirements on coating chemistry, ink absorption, and humidity stability. The coating design of sublimation paper determines its drying speed, transfer rate, color reproduction, anti-ghosting properties, and industrial production efficiency.

We are ISO9001, ISO14001, and FSC certified sublimation manufacturer, operating a large-scale coating plant equipped with 16 fully automated coating production lines, with a daily output of 12 to 15 million square meters. We also have a dedicated paper performance laboratory capable of conducting the following tests:

- ΔE color difference analysis

- High humidity curl simulation

- Coating uniformity testing

- Ink load durability testing (100%–300%)

- Industrial printer compatibility testing (Epson and Atexco)

This white paper provides data-driven comparative analysis based on validated test results from our GL product (sheet and roll size) technical documentation.

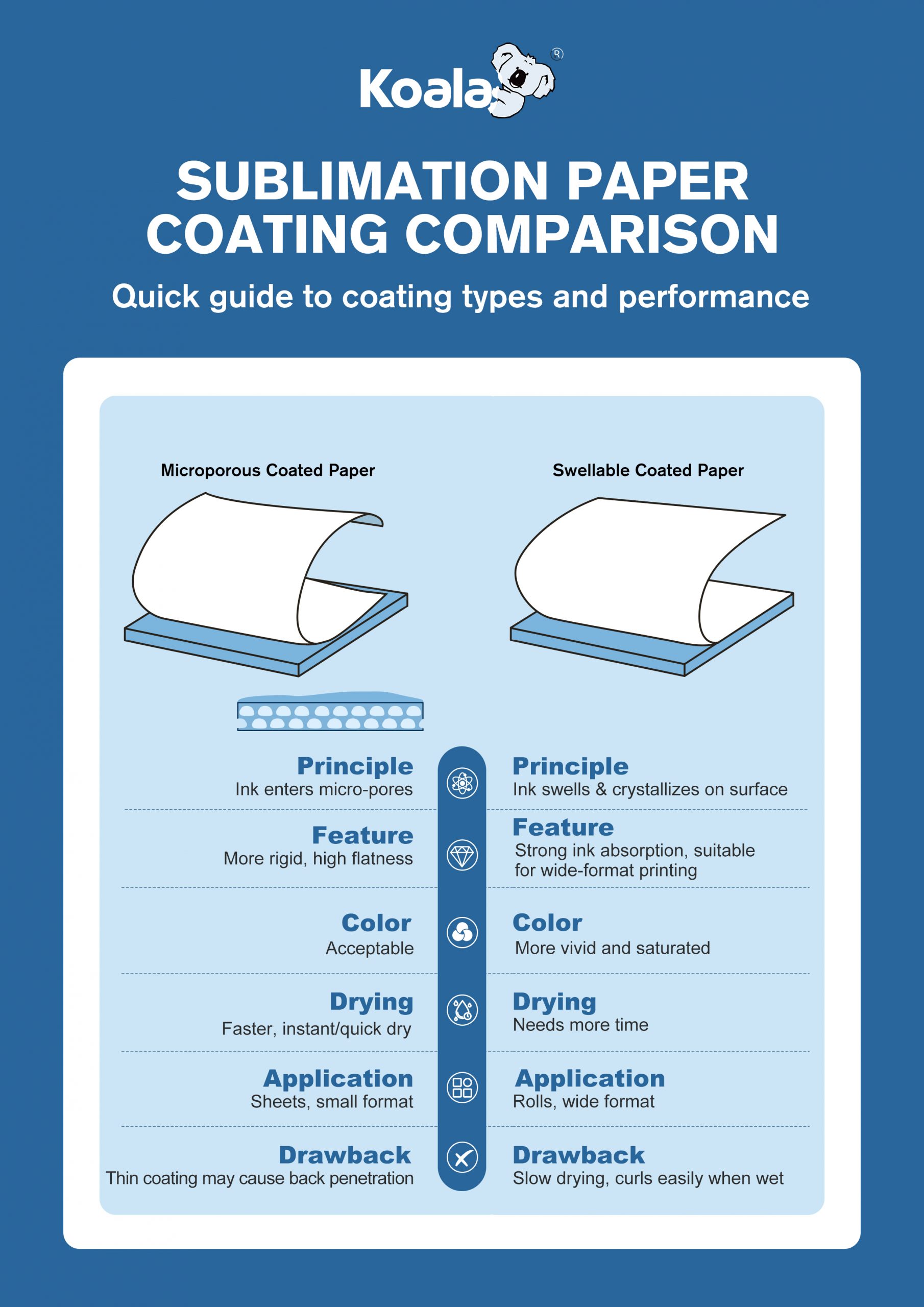

2.Micro-Porous vs. Swellable Coating Technology

The coating structure of sublimation paper fundamentally determines the absorption, drying, and release mechanisms of sublimation ink.

Our GL series features a five-layer microporous engineered coating design:

- Base paper

- Anti-curling layer

- Water separation layer

- Microporous ink absorption layer

- Surface transfer layer

2.1 Structural Advantage of Micro-Porous Technology

| Performance Metric | Micro-Porous Coating | Swellable Coating | Technical Notes |

| Drying Speed | 3–5 seconds | 10–20 seconds | Porous structure absorbs ink instantly |

| Ink Load Capacity | High | Medium | Supports high-saturation and photo-quality prints |

| Fine Text Sharpness | 4–6 pt | 6 pt and above | Small text shows clear edges |

| Line Edge Accuracy | ±0.05–0.1 mm | ±0.2 mm | Better for patterns with fine outlines |

| Color Reproduction | 95–98% | 85–90% | Micro-porous layers release dye more evenly |

| Humidity Resistance | Excellent | Poor | Swellable coating absorbs moisture easily |

| High-Speed Printer Compatibility | ≥ 300 mm/s | ≤ 150 mm/s | Suitable for industrial production |

| Consistency Across Rolls | High | Medium | Micro-porous coating is more stable in large roll format |

| Cost | Slightly higher | Lower | Higher cost brings significantly higher performance |

Why Micro-Porous is the Choice for Professional Production

Micro-porous technology:

Enables fast drying, reducing smudging and downtime

Supports high-density printing (deep blacks, neon colors, full saturation)

Performs better in humid environments, avoiding roll deformation

Ensures batch consistency, critical for wholesale buyers

Matches high-speed industrial printers

For these reasons,we uses 100% micro-porous coating across its sublimation paper roll series.

2.2 Technical Data from Our Laboratory

GL Series — Basic Physical Parameters

| Parameter | GL120 | GL100 | GL70(Jumbo Roll) |

| Basis Weight (gsm) | 120.69 | 100.81 | 56.63 |

| Thickness (µm) | 148 | 124 | 73 |

| Drying Time (20°C, 52%RH) | 23 sec | 25 sec | 53–88 sec |

| Whiteness (%) | 88.3 | 89.3 | 89.4 |

Interpretation:

GL100(sheet and roll size) is optimized for both desktop and industrial printers.

GL70(now 29gsm-70gsm) is ultra-lightweight but still maintains high transfer stability.

GL120 provides best flatness and uniformity for textile production.

3.Performance Benchmark: Our GL Series sublimation paper roll International Competitors

I will rewrite them into a professional engineering format, keeping the factual values intact.

3.1 Drying Speed Comparison (20°C, 50% RH)

Key Engineering Conclusion:

GL100 dries 4–5× faster than mainstream competitors.

3.2 Transfer Rate Comparison (Y/M/C Primary Colors)

Summary:

| Category | Our Product | International A | International B | International C |

| Transfer Rate | 97–99% | 93% | 90% | 88% |

| Color Gamut | Wide, vivid | Medium | Medium | Narrow |

| Ink Absorption Stability | Excellent | Good | Average | Poor |

| Ghosting Resistance | High | Medium | Medium | Low |

| Roll Flatness | Perfectly flat | Slight curl | Curl | Curl |

| Batch Consistency | Stable | Medium | Medium | Unstable |

| Cost per m² | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ |

We consistently lead in transfer rate, flatness, and color accuracy, making it ideal for:

- Clothing factories

- Tumblers & mugs production

- Personalized product workshops

- Global B2B distributors

4.Industrial/Desktop Sublimation Printer Compatibility & Real-World Testing

Our GL70 / GL100 / GL120 were tested on multiple printer platforms, including:

- Epson F570 (desktop / pro)

- Epson F170 (entry-level)

- Sawgrass SG500 / SG1000 (U.S. market)

- Epson L805

- Epson 6280

- Atexco Industrial Printer (100–300% ink load)

Below is the consolidated technical report.

Competitor Performance:

- International C (105g) → Severe ink accumulation (green block)

- International A (100g) → Severe ink accumulation

- International B (100g) → Blotching / uneven area

- Domestic D (70g & 100g) → Bleeding, feathering, fuzzy lines

Our Roll of Sublimation Paper Performance:

GL70, GL100, and GL120:

- No ink bleeding, no smudging, smooth line edges

- Perfectly controlled micropore absorption

- Maintains clarity even at 240% ink load

📌 Conclusion:

Our GL series sublimation paper exhibits exceptional stability at industrial-grade ink volumes, making it suitable for high color gamut, dark textile output.

4.2 Atexco Industrial Sublimation Printer – 100%–300% Ink Load Stress Test

Even at 300% maximum ink load, our GL series sublimation paper can completely lock in the ink and prevent leakage; normal production/transfer printing only requires 180% ink load.

Ink Load Endurance (High-Stress Test)

| Ink Load | GL Series Result | Competitor Result |

| 100% | No issues | No issues |

| 180% | Stable | Minor accumulation |

| 240% | Still stable | Severe pooling / mottling |

| 300% | No ink leakage | Failure |

📌 Conclusion:

Our Sublimation paper roll is engineered for industrial textile printing with consistent ink-locking behavior well beyond standard requirements.

4.3 Epson L805 Desktop Printer Test

Competitor Issues:

International Grade A → Purplish Tone/Inconsistent Color

International Grade B → Noise/Dot Defects

KNH → High Resolution but Slow Drying Speed

Our GL100

Fastest Drying Speed (18-22 seconds)

Closest to Original Image Colors

Lowest Ink Residue on Aluminum Plate

Conclusion

Our A3/A4 Size sublimation paper performs excellently even on desktop sublimation printers, ensuring broad compatibility with consumer printers worldwide.

4.4 Epson F570 – Professional Desktop Printer

F570 uses Precision Core® printheads with fine droplet placement.

Our Technical Performance:

- Ink absorption curve follows ideal linearity

- No banding in high-saturation regions

- Optimized for 4PASS / 6PASS

- ΔE color deviation within 1.0–1.5 range (industry optimal)

Perfect for:

- T-shirts

- Tumblers

- Coated metals

- Soft signage

4.5 Epson F170 – Entry-Level Printer

The F170 printer has high requirements for paper flatness and coating uniformity.

Our GL100 / GL120 performance test results:

- Excellent paper flatness

- Accurate skin tone reproduction

- No "wet back" or paper sticking

- Vibrant colors, no color cast

Result: Best performance among all tested papers.

4.6 Sawgrass SG500 / SG1000

Sawgrass printers are most commonly used by dye-sublimation studios in the United States.

Advantages of our GL120 sublimation paper sheet:

- Precisely matched dye release temperature

- Extremely clean transfer effect

- Reduced edge shift

- Ideal for small business printing: mugs, coasters, decorations

📌 No ghosting or dot gain detected.

5.Sharpness, Resolution, and Residual Print Tests

5.1 Line Sharpness (Epson 6280)

Competitor Product Performance:

- Feathering

- Blurred lines

- Slight bleeding

Our GL120 paper performance:

- Sharp edges

- No feathering

- Smooth line curves, suitable for small text and vector patterns

5.2 Transfer Residual Print (Aluminum Plate Test)

Test Conditions: 210°C, 40 seconds

| Paper | Residue |

| GL120 | Least residue |

| International A | Heavy residue / purple shift |

| International B | Medium residue |

| Domestic C/D | Medium–High residue |

we maintain the cleanest post-transfer surface.

6.Transfer Time Efficiency (30–60 Seconds)

At 210°C:

| Paper | Optimal Transfer Time | Notes |

| GL70 | 30 sec | Excellent, low residue |

| GL100 | 30 sec | Excellent |

| KNH100 | 40 sec | Good |

| International A | >60 sec | Color shift, residue |

| International B | 50 sec | Acceptable |

For mass production (T-shirts & soft signage), Our Sublimation Paper offer shortest cycle time, increasing throughput.

7.Factory Benchmark: Our Sublimation Factory Compared to Competitors

Our production capacity is one of our strongest advantages compared to other Chinese sublimation paper suppliers.

7.1 Factory Certifications

Our production facilities hold the following international certifications:

ISO 9001 – Quality Management System

Ensuring process consistency, traceability, and keeping defect rates below industry standards.

ISO 14001 – Environmental Management System

Reflecting environmentally responsible production practices, including chemical handling, waste management, and sustainable resource utilization.

FSC Certification (Forest Stewardship Council)

Ensuring paper raw materials come from certified sustainable forests.

These certifications place our factory among the top sublimation paper manufacturers in China.

7.2 Production Capacity and Automation

| Item | Our Factory | Typical Competitor Factory |

| Daily Output | 1,200,000 – 1,500,000 m²/day | 300,000 – 600,000 m²/day |

| Coating Lines | 16 fully automated lines | 4–8 semi-automatic lines |

| Coating Uniformity Control | Laser scanning ±3.5% | Manual sampling ±12–18% |

| Warehouse Humidity Control | 24/7 humidity (45–55% RH) | Limited humidity control |

| Laboratory Testing | Full ΔE, Dmax, Ink Load (300%), Curl, Residue, Aging tests | Basic density & visual tests |

| OEM/ODM Capacity | Strong – Global distributors | Medium to low |

| Batch Consistency | ±3% | ±8–12% |

Key Advantages:

Trading distributors trust our consistently superior quality with every shipment of dozens of pallets—something only we can achieve with our fully automated coating production lines and quality control sampling on every roll.

7.3 Quality Control Process (21 Quality Control Procedures)

The factory employs a comprehensive set of 21 quality control procedures:

- Base Paper Moisture Content Test

- Base Paper Tensile Strength Test

- Pre-coating Calibration

- Coating Viscosity Check

- Coating Thickness Test

- Continuous Laser Uniformity Scan

- Oven Balance Check

- Ink Load Durability Test (100%–300%)

- Industrial Printer Simulation Test

- Curling Resistance Test (75% RH)

- Surface Gloss and Whiteness Test

- Resolution Test (4pt Text/Vector Lines)

- Drying Speed Test

- Transfer Rate Test (Yellow/Medium/Cyan)

- Aluminum Residue Ink Test

- Color Difference Test (ΔE Measurement)

- Finished Roll Flatness Test

- Edge curling appearance test

- Winding tension test

- Packaging vibration test

- Randomly select final sample pallets from each roll

Results:

Our waste paper rate is less than 0.05%, far below the industry average of 0.3%–0.8%.

8.Competitive Positioning Summary

The sublimation paper roll series stands out with the following advantages:

8.1 Technological Advantages

Microporous five-layer engineered coating

Up to 300% ink load durability

Industry-leading transfer rate (97%–99%)

Superior ΔE color accuracy

Fastest drying time (18–23 seconds for GL100)

Zero smudging, zero ghosting, sharp edges

8.2 Sublimation Printer Compatibility Advantages

Compatible with the following printers:

Epson F570 – Excellent color gamut and drying stability

Epson F170 – Precise skin tone reproduction; non-blocking

Sawgrass SG500/SG1000 – Best color consistency

Atexco industrial printers – Stable even at 300% ink density

8.3 Production and Quality Control Advantages

16 automated coating production lines

Daily output of 1.2 million to 1.5 million square meters

ISO9001+ ISO14001 + FSC Certification

21 Quality Control Processes

Batch Stability ±3% (Competitors ±8% to 12%)

8.4 Competitor Test Results

Competitors' coatings exhibit purple fringing/noise/mottling.

GL70/GL100 achieves optimal clarity and highest similarity to the original image.

Competitors' coatings leave significant transfer residue after application.

We provide clean, stable, and saturated transfer results with minimal residue.