Introduction

For global distributors, what truly limits growth is often not market demand. Instead, it is the response speed of the supply chain. When large industry orders or peak-season demand are released at once, the delivery capacity of upstream factories directly decides whether orders turn into real revenue.

According to Smithers’ report The Future of Digital Printing Markets 2024, peak-season demand for digital photo and commercial inkjet paper is usually 30%–50% higher than off-season levels. However, the global average effective capacity utilization of coated paper is only about 65%–75%. This means that once production lines lack flexible buffers, supply breaks become a high-probability event.

More realistically, stockouts do not only cause direct sales losses. They may also trigger platform performance checks, OTIF score drops, and traffic weight reductions. For distributors who rely on fast delivery as a core advantage, supply stability itself is becoming a key competitive resource.

For this reason, more distributors now realize that building long-term cooperation with a large-scale photo paper factory is not only about having stock. Instead, it is about creating a stable and reliable safety channel for sustained business growth.

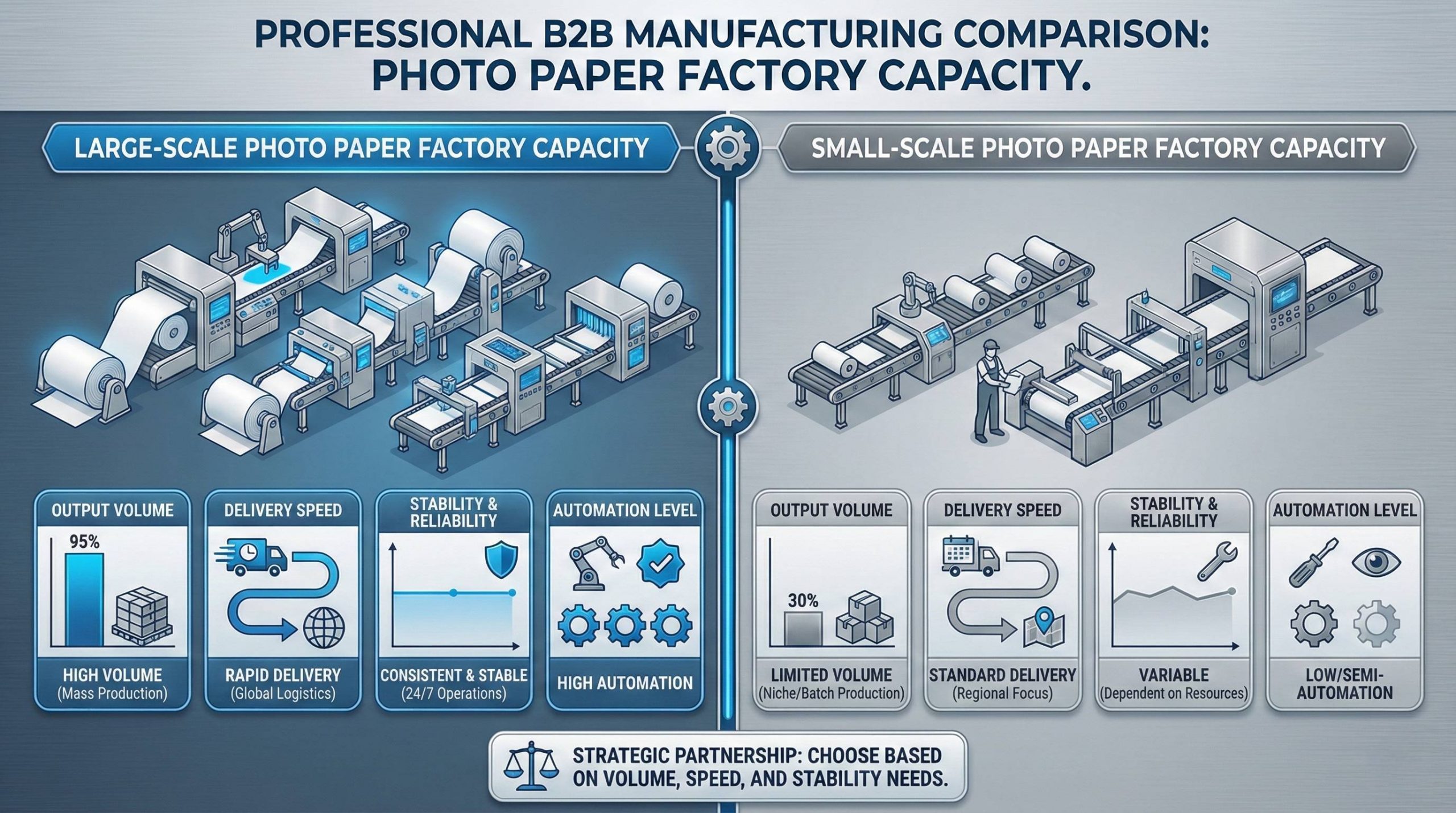

Three Core Values Brought by Large-Scale Capacity

We emphasize “capacity” not because of size alone. In manufacturing, scale often means certainty. Based on Koala Paper’s real delivery capacity of about 200 million square meters per year, we summarize three direct values that large-scale capacity brings to distributors.

Supply Stability: Using “Capacity Buffers” to Offset Market Fluctuations

Small and medium factories usually have only 1–3 coating lines. Once raw materials are delayed or orders surge, delivery flexibility almost drops to zero. However, Koala builds adjustable capacity buffers through a multi-base + multi-line layout. Even if one line is under maintenance, other lines can quickly fill the gap. This structural redundancy forms the foundation of stable supply.

Quality Consistency: Scale Actually Favors Standardized Control

Many buyers assume that large volume means unstable quality. However, from a manufacturing logic view, the opposite is true. Only large-scale factories can invest long-term in automated coating control systems, online inspection, and batch consistency management. Under the ISO 9001 quality system, Koala standardizes process parameters and digitizes production data. As a result, color performance, ink absorption, and surface flatness stay highly consistent across batches.

Cost and Lead-Time Advantage: Scale Determines Response Efficiency

Large-scale production significantly spreads fixed manufacturing costs. At the same time, it narrows fluctuations in unit lead time. This helps distributors maintain stable profit margins during peak seasons. It also allows them to respond faster to market rhythm, instead of waiting passively for production slots.

Koala Factory Capability Overview (Real Manufacturing Dimension)

-

Annual Capacity: About 200 million m²

-

Production Setup: 5 major production bases with about 20 coating lines

-

Processing Capacity: 9 high-speed slitting and rewinding lines

-

Logistics: Supports stable container-level shipments to multiple regions

-

Inventory Strategy: Maintains strategic stock of base paper and key coatings

These configurations are not built to “show scale.” Instead, they serve one core goal: to maintain stable delivery even during demand fluctuations.

A large batch of photographic paper is about to be shipped to destinations around the world.

How Capacity Truly Turns Into Value

Strong manufacturing capacity must finally show up in real product supply. At present, Koala’s capacity mainly supports two product lines with very different demand structures. Strong manufacturing power must prove itself through stable delivery of real products. RC photo paper and cast coated paper, as Koala’s representative products, clearly show how large-scale production continues to support different demand structures.

RC Photo Paper: A Stable Core for the High-End Imaging Market

RC Photo Paper uses a double-sided resin coating structure and microporous ink-receiving technology. It places extremely high demands on clean environments, coating uniformity, and batch stability. This type of product is not only “hard to make,” but also “hard to sustain in large-volume stable production.”

With mature automated coating control systems, Koala’s RC photo paper works well for professional photography output, e-commerce imaging, and high-end commercial inkjet printing. At the same time, it keeps a stable supply rhythm even during peak seasons.

Cast Coated Paper: A High-Volume Product for the Mass Market

Cast coated photo paper is widely used in office printing, advertising output, and daily photo printing. It is a basic product with high standardization and large demand. For distributors, this product competes on stability, cost, and turnover efficiency.

Under conditions of large-scale continuous production, Koala can provide long-term supply at relatively stable unit costs. This makes it well suited for channel distributors and bulk project clients.

A Semi-Case View: What Does Stable Supply Mean for Distributors?

Take one typical overseas distributor we serve as an example.

Its main business focuses on e-commerce imaging and commercial inkjet printing. Its peak-season order volume is usually 1.6–1.8 times that of the off-season. In the early stage, due to limited supplier production lines, stockouts occurred many times during peak seasons. As a result, the company not only lost sales but also suffered from lower platform performance ratings.

After adopting a cooperation model of “locking capacity in advance + phased rolling replenishment,” this client achieved zero stockouts over the last two peak-season cycles. At the same time, its average replenishment cycle was significantly shortened.

This case itself is not complex. However, it explains one realistic logic:

stable supply itself is one of the most underestimated profit drivers for distributors.

How Do We Understand “Sustainable Delivery”?

From a manufacturing perspective, true stable delivery does not rely only on “more production lines.” Instead, it depends on four combined factors:

-

Whether capacity planning includes redundancy

-

Whether core raw materials have safety stock

-

Whether production scheduling supports dynamic adjustment

-

Whether key clients have capacity locking mechanisms in advance

In our practice, moving risks forward is far more important than fighting for capacity afterward. This is also why we prefer to build mid- to long-term cooperation with distributors, rather than short-term spot transactions.

Conclusion: Choosing a Supplier Is Also Choosing a “Growth Safety Boundary”

In today’s uncertain environment, suppliers that “can deliver” are not rare. However, partners that can still maintain stable delivery during fluctuations are becoming harder to find. Stable manufacturing capacity, clear capacity planning, and sustainable delivery systems are the real foundations that support long-term distributor growth.

If you are evaluating the safety of your next-stage supply chain, you are also welcome to learn more about our photo paper product lines. You may also contact us directly to discuss current capacity schedules and cooperation models.