Table of Contents

Toggle1.Introduction

DTF (Direct-to-Film) technology is accelerating the technological upgrade of garment customization by enabling the printing of vibrant, washable designs on any type of clothing/fabric. The core of this DTF printing technology entirely depends on the DTF transfer consumables: DTF film rolls. While many users/distributors understand how to operate DTF printers/powder shakers, few have a deep understanding of the transfer film itself—including its structure, chemical composition, coating technology, and how these factors directly impact print quality, transfer effect, washability, and production efficiency.

This article is written by the technical team of Koala® Factory, one of China's leading manufacturers of coated dtf PET printing film. With years of experience in PET coating, ink absorption technology, and large-scale roll production, we aim to provide the most comprehensive and professional explanation of DTF film rolls.

Whether you are a printing factory, wholesaler, or distributor, this guide will help you understand:

- What is a DTF film roll?

- How the coating works

- Why different types of film exist

- How to choose the right roll size

- Which technical specifications are truly important

- How to avoid common printing problems

- Why factory-grade coating technology is crucial

This is not just an introductory article—it's an in-depth guide designed for professional users who demand consistent quality and industrial-grade performance.

2.What is a DTF Film Roll?

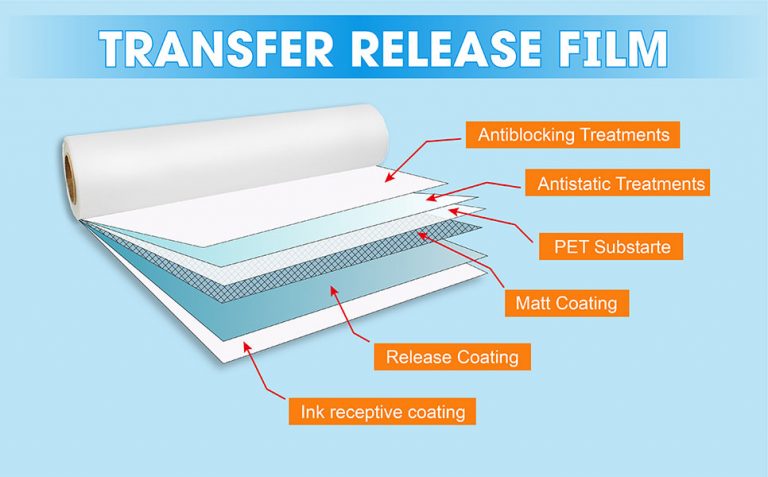

DTF film roll is a specially coated PET (polyethylene terephthalate) film designed to absorb DTF ink, creating personalized transfer films. It uses TPU hot-melt adhesive powder and a heat press process to transfer various small images onto fabrics. Unlike traditional T-shirt transfer paper and sublimation paper, DTF film rolls must withstand high-temperature curing, precise ink absorption and powder adhesion, while maintaining dimensional stability and image clarity.

DTF Film Roll = PET Base Film + Functional Coating (Koala® Exclusive)

DTF transfer film roll is not simply "plastic." Its structure is precisely designed and composed of multiple functional layers, typically including:

1.PET Base Film (common thickness: 75µm / 100µm)

- Provides strength, smoothness, and thermal stability

- Does not stretch or deform during heating

- Determines the film's handling and rigidity

2.Ink Absorption Layer

- The key layer for DTF printing

- Controls the amount of ink absorbed

- Ensures clear and vibrant colors

- Prevents ink bleeding, spreading, or blurring

3.Anti-static Layer (optional)

- Reduces dust contamination

- Prevents powder from adhering to unwanted areas

- Moisture-proof/anti-curling treatment

- Keeps the film flat under different temperature and humidity conditions

4.Anti-stick Layer (for cold peel/hot peel)

- Controls the ease of peeling the film after heat pressing

- The fundamental difference between hot peel and cold peel

5.Why choose PET film as the base film for Direct to Film?

PET material is chosen because it has the following advantages:

- High temperature resistance

- Excellent transparency

- Superior dimensional stability

- Chemical compatibility with DTF coatings

- Smooth surface ensuring uniform coating

- Does not shrink during the curing process at 120–160°C

6.Why is the “coating” more important than the film itself?

In DTF heat transfer printing, 90% of printing quality problems stem from the coating, not the physical properties of the film. If the coating is unstable, users may encounter the following problems:

- Ink bleeding

- Low color saturation

- Uneven powder adhesion

- Spots or pinholes

- Poor wash fastness

- Peeling issues

This is why the quality of DTF PET film rolls varies greatly among different factories—even if they all claim to be "hot peel, cold peel, or double-sided matte." However, the coating formulation and the factory's coating capabilities are the real key factors determining the film quality.

3.Material Structure & Coating Technology

DTF film rolls are not simply coated PET material, but a new type of transfer printing consumable produced using precision coating machinery. Their structural design and coating chemical composition directly determine the print quality, powder adhesion, wash fastness, and peeling performance.

The following will provide a detailed introduction to the manufacturing process of high-quality DTF films, especially the production process of professional DTF roll coating factories.

3.1 PET Base Film Structure

Most Heat Transfer films use 75µm or 100µm PET base films. The choice affects stability, rigidity, and printability.

PET Base Film Grades

| Grade | Description | Stability | Use Case |

| A-Grade PET | High transparency, low shrinkage | ★★★★★ | Premium DTF Rolls (Koala standard) |

| B-Grade PET | Slightly uneven clarity | ★★★★☆ | Budget rolls |

| C-Grade PET | Higher shrinkage, impurities | ★★☆☆☆ | Cheap non-brand films |

High-quality factories like Koala® only use A-grade PET for consistent production.

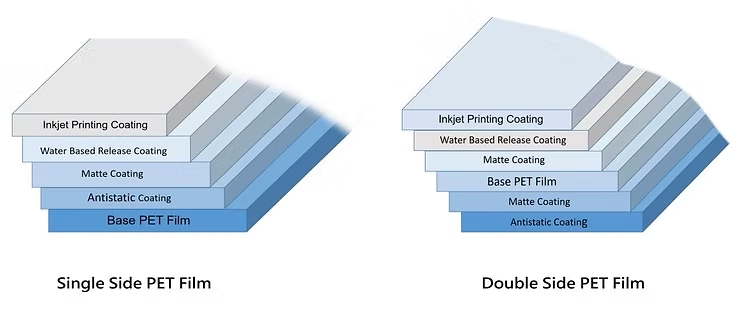

3.2 Single-Sided and Double-Sided Coating Structures

PET film rolls for DTF printing mainly come in two coating structures, each with its unique advantages.

Single-Sided Coating (Single-Sided Matte):

- One side coated with an ink-absorbing layer

- The other side is smooth PET material

- More cost-effective

- Suitable for mass production

Double-Sided Coating (Double-Sided Matte):

- Both sides are matte treated

- Better anti-static performance

- Stronger moisture resistance

- Superior flatness

- Prevents back-to-back adhesion (when stacking printed items)

Our factory can provide both types of DTF film structures according to customer needs.

3.3 Matte and Glossy Coatings

You may see some films described as "matte," "semi-matte," or "glossy." These terms relate to surface friction and how the coating scatters light.

| Type | Surface | Advantages | Ideal For |

| Matte | Rough, anti-glare | Easy powder flow, stable ink | Most DTF users |

| Semi-Matte | Balanced | Strong colors | Premium prints |

| Glossy | Smooth | High detail sharpness | Special effects |

Most industrial users prefer double matte due to stability.

3.4 Coating Chemistry: The Core of DTF Performance

Why Coating Matters?

The coating determines:

- Ink loading capacity

- How pigments stay suspended

- Drying speed

- How evenly powder adheres

- Final wash resistance

- Peel performance

The coating typically includes:

- Ink Absorption Polymers

- Control surface energy

- Ensure smooth ink landing

- Prevent spreading or bleeding

Crosslinking Binders

- Bind pigments to coating

- Improve wash durability

- Prevent pigment cracking

Surface Tension Modifiers

- Control dot sharpness

- Reduce bleeding around edges

Matting Agents

- Create matte finish

Improve powder flowability

Release Agents

Determine hot peel or cold peel behavior

Different factories use different formulas.

Koala® Factory applies multi-stage coating with controlled thickness, resulting in:

- High ink capacity

- Sharp color boundaries

- No pinholes

- Smooth powder application

- Consistent peel behavior

3.5 Precision Coating Technology: Why Factory Matters

Professional DTF film production requires:

✔ Precision Coating Machines (Wide-Format)

Ensure consistent coating thickness from edge to edge.

✔ Strict Tension Control System

Prevents film deformation during drying.

✔ Drying Oven Curve Control

The heating curve affects:

- Coating hardness

- Adhesion strength

- Curling resistance

A high-end factory like Koala® uses multi-zone drying ovens to optimize coating crosslinking.

✔ Cleanroom Production

DTF film is sensitive to dust; therefore, coating must be done in low-dust environments.

✔ Inline Defect Detection Systems

Detect:

- Pinholes

- Scratch marks

- Uneven coating

- Backside contamination

4.How DTF Printing Works

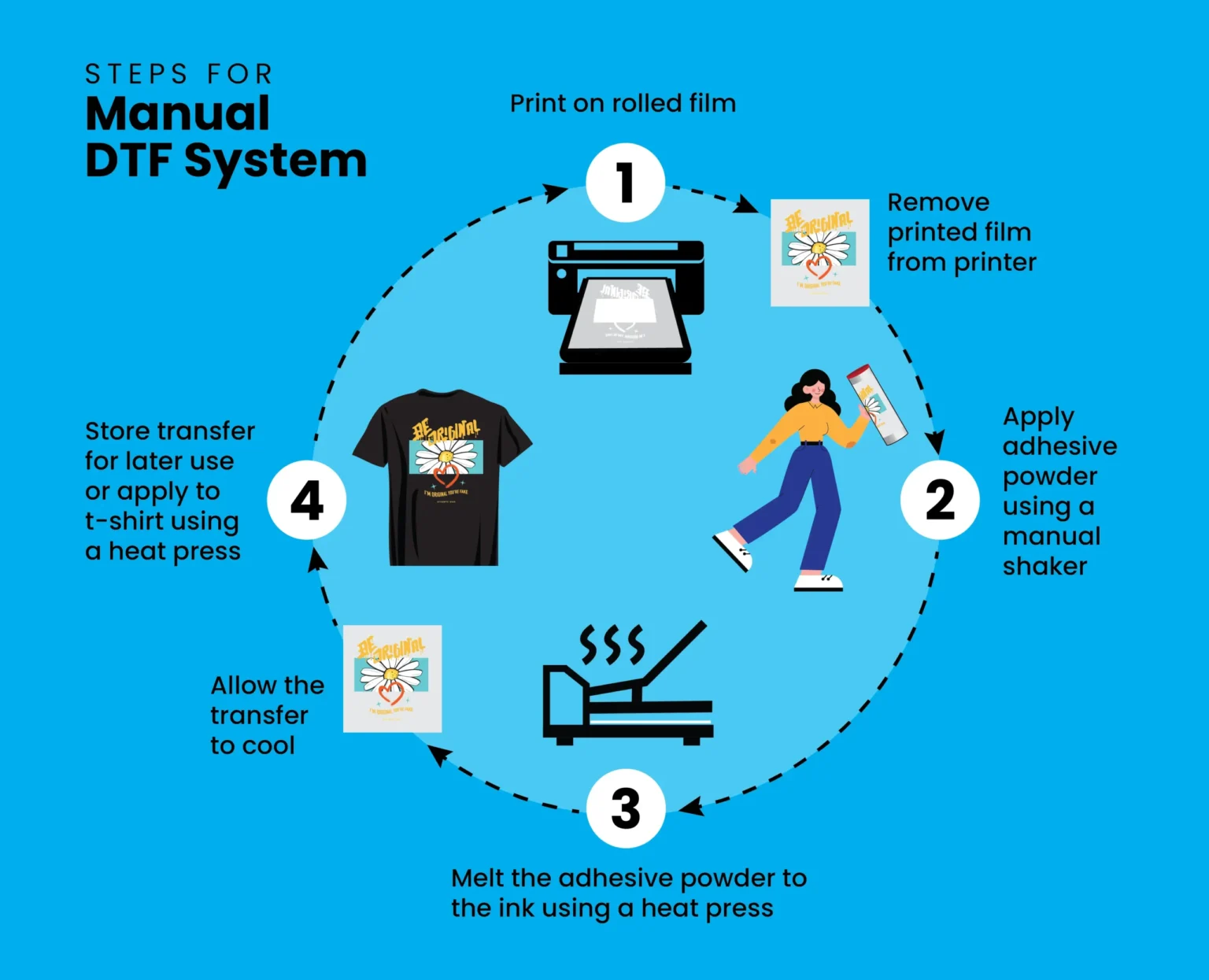

DTF printing is a relatively complex and comprehensive transfer process involving ink, coating, hot-melt adhesive powder, and heat pressing. Each step is crucial for the final transfer pattern to be flexible, durable, and vibrant in color. The following section explains the principles of the workflow.

4.1 DTF Printing Step-by-Step Process

Step 1: Printing on DTF PET Film

The printer first prints CMYK pigment inks, and then adds a layer of white ink as a base coat behind the colors.

Color → White

Why? Because white acts as an opaque base color, enhancing color vibrancy and preventing bleed-through on the fabric. This white base layer is crucial for DTF printing to be suitable for any fabric.

The quality of the film at this stage largely depends on:

- Ink absorbency of the film coating

- Printer color profile

- Ink droplet accuracy

Our exclusive absorbent coating ensures instant ink adhesion, preventing spreading and maintaining clarity.

Step 2: Applying Adhesive Powder

Hot-melt adhesive powder (TPU-based) is sprinkled onto the wet ink layer. The powder only adheres to:

- Areas covered by ink

- This is due to the surface energy control of the coating

If the film coating is unstable, the DTF powder may adhere unevenly, leading to:

- White spots

- Rough texture

- Poor washability

Step 3: Powder Melting/Curing (120–160°C)

The printed film enters an oven or shaker, during which:

- The powder melts

- The melted powder bonds with the ink layer

- The coating dries and fixes the pigments

The curing temperature stability of the DTF powder is crucial.

- If the temperature is too low → the powder does not melt completely (weak adhesion)

- If the temperature is too high → PET deformation or yellowing

We offer several types of TPU powder to choose from, suitable for different needs.

Step 4: Cutting or Stacking

After curing:

- The film dries and can be cut

- The printed patterns can be stacked without sticking together (especially suitable for double-sided matte structures)

Step 5: Heat Press Transfer

At a temperature of 150–170°C, the melted powder becomes a viscous substance again and bonds with the fabric fibers. This interaction determines:

- Washability

- Tensile strength

- Hand feel (soft or stiff)

The combination of high-quality DTF film + high-quality powder achieves:

- Soft, flexible prints

- No cracking

- Strong adhesion even after 30-50+ washes

Step 6: Peeling (Hot Peel/Cold Peel/Warm Peel)

Peeling effect depends on:

- Coating release agent formulation

- Drying curve during the coating process

- Surface tension

Hot Peel DTF Film

- Immediate peeling

- Faster workflow

- Slightly less tolerance for temperature errors

Cold Peel DTF Film

- Peeling after cooling

- More user-friendly for beginners

- More suitable for large-scale production

Our DTF Roll offers two solutions to meet different customer needs.

4.2 The Science Behind DTF Printing

① Ink → Coating Interaction

The coating must balance:

- Fast ink absorption

- High ink carrying capacity

- Clear dot formation

If absorption is too slow → smudging will occur

If absorption is too fast → colors will darken

We use a microporous coating technology similar to sublimation paper to ensure color saturation without bleeding.

② Hot Melt Powder → Ink Layer Fusion

The hot melt powder melts at 110–130°C.

It forms:

- A flexible TPU layer

- An adhesive bridge between the ink and the fabric

- Provides protective elasticity, washability, and stretch resistance

Powder quality affects:

- Hand feel (soft or rubbery)

- Durability

- Stretch performance

③ Heat Press → Fabric Bonding

During the heat pressing process:

- The powder melts again

- The ink + powder layer is embedded in the fabric texture

- Cooling solidifies the bond

High-quality film prevents:

- Edge lifting

- Cracking

- Matte whitening during peeling

④ Peeling Performance Design

Hot peel or cold peel effect depends on:

- Release layer chemical composition

- Coating curvature under heating

- Surface friction

Our designed release layer ensures:

- Clean peeling

- No ghosting

- No cracking at the edges

5.Heat Resistance & White Ink Performance

High-temperature resistance is one of the most important characteristics distinguishing high-end and low-end DTF film rolls. During the DTF film production process, the printed film must be able to withstand:

- Curing temperatures of 120-160°C

- Direct contact with heating elements (tunnel dryers/ovens)

- Thermal expansion and tensile stress

- Adhesion of hot-melt powder in a wet state

If the DTF film fails under any of these stress conditions, it will lead to unstable printing results, defects, or durability problems.

5.1 The Importance of Heat Resistance in DTF Printing

High-temperature curing is an essential step in the DTF solution.

The film must remain:

- Flat

- Undeformed

- Chemically stable

- Dimensionally stable

During the curing process at temperatures up to 160°C, inferior films may experience the following problems:

- Shrinkage

- Warping or curling

- Bubble formation

- Cracking of white ink

- Adhesion to the oven surface

All of these can lead to batches of DTF film being scrapped in mass production.

5.2 PET Thickness = Stability

Most DTF films use 75µm or 100µm PET base films.

| PET Thickness | Thermal Stability | Softness | Recommended Use |

| 75µm | Medium | Softer | Retail users, desktop printers |

| 100µm | Higher | Stiffer | Factory-level continuous production |

Thicker PET = Better reliability under high heat.

This is why our factory-grade DTF film for roll production uses highly stable 100µm PET.

5.3 White Ink Performance = 70% Dependent on the Coating

DTF printing uses a three-layer printing structure:

- CMYK ink printed on top

- White ink printed on the bottom

- Hot melt powder adheres to the white ink layer

If the chemical coating performance is poor, white ink problems will occur

Common white ink problems caused by low-quality film:

- White ink spreading or bleeding

- Weak adhesion to the powder

- Cracking of the white ink layer after washing

- "Orange peel" texture on the surface

- Powder unable to adhere evenly

- Spots or pinholes in the white ink layer

These problems directly affect wash fastness and color stability.

5.4 What Factors Determine White Ink Quality?

① Ink Absorption Rate

The coating must be able to absorb a large amount of ink without ink accumulation.

② Surface Energy Control

Ensuring the white ink is smooth and even.

③ Chemical Interaction with Pigments

The coating must fix the pigments in place during the high-temperature curing process.

④ Powder Adhesion Compatibility

The surface must be properly activated to allow the powder to adhere evenly.

These characteristics stem from precise coating formulations and process control – an area where our factory excels with years of experience in industrial-grade coating production lines.

5.5 Our DTF Factory Advantages – High-Temperature Coating and PET Stability

Our DTF film coating is designed for the following characteristics:

- 160°C high-temperature curing stability

- Zero shrinkage PET base film

- Uniform coating thickness ±0.2μm

- Anti-bubble and anti-curling surface treatment

- Optimized white ink adhesion

This makes Koala® film suitable for high-speed roll-to-roll printers, such as:

- DTF printers based on Epson i3200 / XP600 printheads

- Ricoh printhead DTF printers

- Industrial-grade 60cm / 90cm / 120cm DTF roll printers

6.Types of DTF Film in the Market

There are several types of direct-to-film (DTF) rolls on the market, each designed for specific production needs, printing environments, and workflows. Understanding these differences helps distributors, printing factories, and wholesalers choose the appropriate type of DTF film.

They are mainly divided into three categories:

- Cold Peel DTF Film

- Hot Peel DTF Film

- Cold and Hot Peel (Universal) DTF Film

6.1 Cold Peel DTF Film

Cold peel film requires waiting 5-10 seconds after heat pressing for the film to cool before peeling it off.

Advantages

- Extremely high transfer stability

- Suitable for large images or fine details

- Smooth matte surface

- Lower risk of stretching during peeling

- Excellent washability

Limitations

- Slower workflow (must wait for cooling)

- Not suitable for high-volume, high-speed production

- Requires stable heat press temperature

Who should choose it?

Factories requiring stable and consistent output

Designs containing fine lines, small text, or intricate patterns

6.2 Hot Peel DTF Film (Fast Production Type)

The film can be peeled off immediately after lifting the heat press, without waiting.

Advantages

- Faster production speed

- Ideal for on-site shops, live printing, events, etc.

- No cooling time required

- Increased daily output

Limitations

- Slightly sensitive to heat press temperature

- Some lower-end films may have the following problems:

- Film stretching

- Peeling residue

- Uneven matte surface

Who should choose it?

- Customers who prioritize efficiency over precision

- Small studios with urgent orders

- Retail stores

- Print-on-demand setups

- High-volume production prioritizing quality

6.3 Universal (Cold and Hot Peel) DTF Film

This is a high-quality, most flexible type that has emerged in recent years.

This film can be:

- Hot peeled

- Warm peeled

- Cold peeled

All with consistent results.

Advantages

- Easiest to use

- Widely compatible with different heat presses

- More stable in high humidity environments

- Easier for beginners to use

- Reduces product returns and user errors

- Ideal for multi-machine environments

Limitations

- Requires advanced coating technology

- Higher production costs

- Not all factories can achieve consistent quality

Who should choose it?

- Distributors serving a wide range of customers

- Factories with various printing equipment

- B2B wholesalers striving for the lowest complaint rate

- Brands positioned for high-end quality

6.4 Koala® Factory’s DTF Film Product Positioning

Koala® offers two main DTF film roll solutions based on market demand:

① Universal Release Coating (Flagship Version)

- Compatible with hot peel, warm peel, and cold peel

- Stable high-speed roll-to-roll operation

- Preferred by US/EU distributors

- Best-selling product for OEM brands

② Cold Peel Release Coating (Industrial Grade Fine Version)

- Ultra-high stability, suitable for large-scale production

- Preferred by textile factories

- Most suitable for fine patterns and small text

- Excellent wash fastness

6.5 How to Choose the Right DTF Film?

| Type | Speed | Detail Quality | Ease of Use | Wash Fastness | Recommended For |

| Cold Peel | ★★★ | ★★★★★ | ★★ | ★★★★★ | Factories, complex designs |

| Hot Peel | ★★★★★ | ★★★ | ★★★★ | ★★★★ | Retail/end-users, POD |

| Universal Peel | ★★★★★ | ★★★★★ | ★★★★★ | ★★★★★ | Distributors, studios, mixed environments |

7.DTF vs Other Printing Methods

DTF (Direct-to-Film) printing's advantage lies in its versatility: one roll of film, any fabric, full-color images, small or large production runs.

To help buyers and distributors better evaluate DTF film, this chapter compares DTF with four main printing systems:

- Sublimation printing

- HTV (Heat Transfer Vinyl)

- Screen printing

- UV DTF

Each method has its own advantages and best application scenarios.

7.1 Comparison of DTF and Sublimation Printing

How Sublimation Printing Works

Dye sublimation transfers ink into polyester fibers at high temperatures.

Advantages of Sublimation Printing

- Vibrant and saturated colors

- Soft feel (no film on the surface)

- Extremely durable on polyester fibers

- Ideal for sportswear and mugs

Limitations

- Only suitable for polyester fibers (≥ 65%)

- Only suitable for light-colored fabrics

- Not suitable for cotton

- Not suitable for dark garments

- Hard products require a polyester-coated substrate

Advantages of DTF over Sublimation Printing

- Suitable for any fabric: cotton, polyester, nylon, blends, canvas, leather

- Suitable for dark fabrics (white ink layer)

- More vibrant colors on cotton than sublimation

- Can create highly detailed images

- Suitable for soft and thick materials

- Ideal for small-batch custom orders

Conclusion

Sublimation printing = Best for polyester fibers

DTF = Best all-around solution

7.2 Comparison of DTF and HTV (Heat Transfer Vinyl)

How HTV Works

Vinyl sheets are cut and heat-pressed onto garments.

Advantages of HTV

- Durable

- Ideal for letters and logos

- Various textures (flocked, glitter, holographic)

Limitations

- Requires cutting and weeding

- Not suitable for fine graphics

- Multi-color layering is time-consuming

- Feels thicker on fabric

Advantages of DTF compared to HTV

- No weeding or cutting required

- Ultra-fine details (small text, gradients)

- Fast for small batch orders

- Time and labor-saving

- Thin, soft, and flexible surface effect

Conclusion

HTV = Best for simple, single-color graphics

DTF = Best for full-color, photographic quality graphics

7.3 Comparison of DTF and Screen Printing

How Screen Printing Works

A screen pushes ink onto the fabric.

Advantages of Screen Printing

- Best for large-scale production

- Vibrant colors on all fabrics

- High durability

- Low cost for mass production

Limitations

- High setup costs (screens, inks)

- Not suitable for small batch orders

- Limited detail

- Long preparation time

- Multi-color printing requires multiple screens

Advantages of DTF compared to Screen Printing

- No screen making required

- Ideal for small batch and custom orders

- Supports photographic images

- Short preparation time

- Higher profit margin for printers

Conclusion

Screen Printing = Best for bulk orders

DTF = Best for on-demand printing and digital detail printing

7.4 DTF vs. UV DTF

How UV DTF Works

UV ink is printed onto a film and then transferred to a hard surface.

Advantages of UV DTF

- Ideal for products such as bottles, laptops, and water cups

- High definition

- Scratch-resistant

Limitations

- Not suitable for textiles

- Hard surface, similar to a sticker

- Stiff feel

Advantages of DTF compared to UV DTF

- Suitable for fabrics (UV is not)

- Soft, breathable, and elastic

- More suitable for clothing

- More comfortable to wear

Conclusion

UV DTF = Best for hard products

DTF = Best for textiles

7.5 Summary Comparison Table

| Method | Best For | Works on Cotton? | Works on Dark Fabrics? | Detail Level | Setup Cost | Feel |

| DTF | Apparel, mixed fabrics | ✔ | ✔ | ★★★★★ | Low | Soft & flexible |

| Sublimation | Polyester items | ✖ | ✖ | ★★★★ | Low | Ultra-soft |

| HTV | Simple logos, letters | ✔ | ✔ | ★★ | Medium | Thick |

| Screen Print | Large orders | ✔ | ✔ | ★★★ | High | Soft (depends on ink) |

| UV DTF | Hard surfaces | ✖ | ✖ | ★★★★ | Medium | Hard, sticker-like |

8.Common DTF Printing Problems & Professional Solutions

8.1 TPU Powder Adhesion Problems

Powder adhesion is one of the most common challenges in DTF printing. If the adhesive powder fails to properly adhere to the printed ink layer, the final transfer effect may suffer from issues such as peeling, incomplete edges, or reduced durability.

Common Causes:

- Ink coating is too thin or uneven

- Humidity affects ink viscosity

- Low-quality DTF powder

- Incompatibility between the film coating and the printer's ink

Solutions:

- Increase white ink density in the RIP settings

- Maintain the working environment humidity between 40-60%

- Use high-purity powder with uniform particle size

- Ensure the film has a stable anti-static and highly absorbent coating

Koala® Factory Advantages:

Koala® DTF film rolls feature a uniform microporous coating design, ensuring optimal powder absorption and maximizing transfer durability.

8.2 Curling and Static Electricity Issues with PET DTF Film

Film curling and static electricity problems are usually caused by improper storage of the film roll or printing under unstable environmental conditions.

Problems:

- Film edges curling up during printing

- Uneven powder distribution

- Film attracting dust or fibers

- White ink splashing or misplacement

Causes:

- Improper storage temperature

- High static electricity generated by friction

- Using low-quality PET base film

- Excessive temperature during the curing process

Solutions:

- Store the film in an environment of 20–28°C and 40–60% humidity

- Use anti-static PET film (Koala standard)

- Gently preheat the film before loading

- Ground the printing equipment to reduce static electricity buildup

8.3 Ink Bleeding and Excessive Absorption

Ink bleeding occurs when the film absorbs too much ink or the coating fails to stabilize the pigment particles.

Phenomena:

- Blurred edges

- Low color saturation

- Halo around white ink

- Dot gain affecting fine details

Causes:

- Excessive use of colored ink

- Poor quality coating

- Unstable drying environment

- Incorrect ICC/RIP ink limit settings

Solutions:

- Reduce the amount of colored ink while increasing the opacity of the white ink

- Use a film with a highly stable coating (e.g., Koala's nanoporous layer)

- Maintain a constant drying airflow

- Enable "dot control" or "ink suppression" features in the RIP software

8.4 Pattern Cracking After Washing

If the cured powder layer is too brittle or the adhesive is not fully melted, cracking may occur after washing.

Reasons:

- Curing temperature too low

- Over-curing leading to brittle powder

- Insufficient elasticity of the PET coating

- Improper fabric pre-treatment

Solutions:

- Follow the powder melting curve (Koala recommends 110-125°C, 70-90 seconds; specific parameters may vary)

- Avoid over-baking

- Use a highly elastic coating film

- Choose fabrics with good surface tension and high cleanliness

8.5 DTF White Ink Clogging and Layer Separation

White ink contains titanium dioxide, which is prone to sedimentation and clogging.

Reasons:

- Prolonged downtime without stirring

- Low working environment temperature

- Unstable ink absorption of the film

- Incorrect RIP layering sequence

Solutions:

- Stir the white ink daily

- Maintain the printing environment temperature at 20-28°C

- Use high-ink-absorbing film to fix the white ink

- Set the correct printing mode: CMYK → White or double printing for high detail results

Koala® Suggestion:

Use Koala® DTF film + high-quality DTF ink + hot melt powder for optimal compatibility.

9.Why Choose Koala® Factory DTF Film Roll

Our DTF Factory is one of China's leading DTF film manufacturers, specializing in inkjet media, sublimation media, and advanced DTF film technology. With over 20 years of coating experience, we have become the primary supplier for many global distributors, large printing studios, and garment factories.

Our factory boasts:

- Over 20 high-precision coating production lines

- Annual production capacity exceeding 200 million square meters

- ISO9001 certified quality management system

- Dust-free cleanroom designed specifically for inkjet coating

- Independent R&D team dedicated to DTF coating chemistry and PET base film optimization

- Our DTF film rolls are not just a printing material, but the culmination of engineering technology, chemical research, and rigorous quality control.

9.1 Advanced Coating Technology

Our DTF transfer films utilize a multi-layer nanoporous coating system, specifically optimized for pigment-based DTF inks. Our coatings offer the following advantages:

- Ultra-stable ink absorption performance

- Fast-drying surface

- High white ink opacity

- Anti-static properties

- Clean and easy peel-off after transfer

Each batch of coating undergoes particle distribution testing, ink droplet spreading testing, and humidity resistance simulation to ensure consistently high performance.

Our R&D team also continuously conducts experiments in the following areas:

- Multi-resin mixtures

- Powder adhesion enhancers

- High-elasticity PET treatment

- Heat-stable formulations for roll-to-roll printing

This is why Koala® films maintain stable performance on various DTF printers, including Epson i3200, 4720, XP600, or Roland modified printers.

9.2 Stable Release and Excellent Washability

One of the biggest advantages of Koala DTF film rolls is the stability of the release after curing and heat pressing. Its coating ensures that the film separates cleanly and easily, leaving no powder residue, cracking, or color fading.

Durability Test Results:

- No fading after more than 50 wash cycles

- No cracking on elastic fabrics

- Excellent adhesion on cotton, polyester, blends, canvas, nylon, and other fabrics

We conduct comprehensive laboratory testing, including:

- Washability testing (ISO 6330)

- Tensile and tear strength testing

- High-temperature peel testing

- UV aging simulation testing

These testing procedures ensure that every roll of film meets international durability standards.

9.3 Dust-Free and Stable Production Environment

DTF film requires highly stable coating conditions. Our factory features:

- Class 10,000 cleanroom coating workshop

- Constant temperature curing tunnel

- Real-time humidity monitoring

- Automated slitting and roll inspection

This ensures:

- No dust particles on the coating surface

- No coating bubbles or micro-defects

- Better powder adhesion

- Excellent transfer clarity

Koala® stable production environment directly guarantees the stability of your printing process.

9.4 Global Quality Standards and OEM/ODM Capabilities

Koala® factory supplies DTF film to distributors in the following regions:

- United States

- Europe (Germany, France, Spain, Italy)

- Southeast Asia

- South America

- Middle East

We offer the following services:

- Custom width and roll length

- Private label packaging

- Custom coating formulations

- Comprehensive OEM brand development

Koala® quality control system ensures:

- Batch traceability

- Standardized coating thickness

- Uniform tensile strength

- Consistent color output in mass production

9.5 Why Koala® DTF Film Rolls Offer Superior Performance

Summary of Koala® DTF Film Roll's Core Advantages:

Choosing Koala means choosing:

- Higher printer compatibility

- Smoother film peeling

- Stronger washability

- Fewer printing defects

- Higher DTF ink compatibility

- Reliable factory-grade quality

Koala® DTF transfer film rolls are designed to provide users with:

✔ Higher production efficiency

✔ Less waste

✔ Lower maintenance costs

✔ More stable and consistent color and detail

Conclusion:

Why DTF Film Rolls are the Future of Garment Decoration

DTF PET film rolls have rapidly become one of the most versatile and efficient digital printing technologies in the global apparel market. Its ability to print vibrant colors, thick white ink layers, fine details, and stretchable designs has quickly made it an ideal choice for businesses of all sizes—from startup studios to large garment factories.

Compared to traditional printing technologies such as sublimation, heat transfer, DTG, and screen printing, DTF offers the following unique advantages:

- No material limitations (suitable for various fabrics including cotton, polyester, blends, nylon, canvas, etc.)

- High durability and washability

- Smooth production process

- Low entry cost and high production efficiency

- Excellent roll-to-roll production scalability

For global distributors and printing brands, choosing a reliable DTF supplier is fundamental to long-term success. The difference between inferior and high-quality DTF film is evident in every aspect—printing, powdering, curing, transfer, and post-wash durability.

This is where Koala® stands out.

With advanced coating technology, precision manufacturing, strict quality control, and over 20 years of expertise in inkjet media, Koala provides DTF film rolls that meet the demands of modern production—stable, consistent, and globally trusted.

Whether you are building your own DTF brand, seeking wholesale procurement, or expanding your on-demand printing business, Koala's DTF film rolls will give you a competitive edge in quality, consistency, and long-term reliability.

DTF is the future.

Koala® helps you achieve that future.

What thickness of DTF film roll should I choose for my printer?

The most common thicknesses are 75μm, 100μm, and 120μm.

75μm → More flexible, suitable for fast production and roll-to-roll printers.

100μm → Most universal; ideal for both sheet-fed and roll-fed printers.

120μm → More stable, excellent for small studios requiring easy handling.

Koala® Factory provides all thickness options and supports OEM specifications.

Is your DTF film compatible with all DTF printers?

Yes. Koala® DTF Film Roll is compatible with Epson, Mimaki, Roland, Audley, Sublistar, Oric, and all desktop-converted DTF printers.

Ink compatibility includes CMYK + White pigment ink from all major brands.

What is the difference between hot peel, warm peel, and cold peel?

Hot Peel – Peel immediately; best for mass production.

Warm Peel – Peel after 5–10 seconds; more stable for beginners.

Cold Peel – Peel after full cooling; best print durability and smoothest surface.

Koala® provides all three peeling types depending on your production needs.

Can Koala® Factory provide stable long-term supply for distributors?

Absolutely. Koala® Factory operates high-volume PET coating lines with a monthly capacity of over 2,000,000 m².

We also provide:

Long-term price protection

Inventory support

White-label & OEM packaging

Custom widths and lengths

What is the minimum order quantity (MOQ) for DTF film roll?

MOQ for bulk orders usually starts at:

20–50 rolls for mixed models

200–500 rolls for custom OEM packaging

For large distributors, Koala® supports container-level loading.

What quality tests does Koala perform on each batch?

Every batch undergoes:

Ink absorption test

White-ink stability test

Powder adhesion test

Transfer durability test (wash test 20+ cycles)

Anti-static & anti-humidity testing

How should DTF film rolls be stored for best performance?

Store in:

Dry environment (40–60% humidity)

Temperature 15–30°C

Away from direct sunlight

Keep sealed until use

Can Koala® provide samples for testing?

Yes, sample rolls and sample sheets are available for:

Printer compatibility testing

Ink absorption

Color performance

Peel tests