Sublimation printing technology continues its rapid development in the global textile and personalized gift industries. However, both large studios and paper roll trading distributors struggle to find manufacturers of consistently high-quality, high-performance, and reliable sublimation paper rolls.

As a professional sublimation paper manufacturer, we fully understand the significant differences between the paper produced in our factory and that sold by trading companies.

This guide shares factory-level knowledge, explains the sublimation paper roll production process, and provides practical advice to help textile mills and interested trading distributors select the right products and solve common challenges.

Table of Contents

Toggle1.Partnering with genuine dyesublimation paper manufacturers is crucial.

In many markets, especially in Asia and Africa, sublimation paper is widely distributed by trading companies lacking technical support and whose paper quality cannot be guaranteed. Their products are often sourced from different manufacturers, resulting in significant differences in quality between batches of sublimation paper rolls, severely impacting the production and distribution of B2B clients.

From our factory's perspective, a good sublimation paper depends on:

- Base paper stability (moisture control, flatness, tensile strength)

- Coating quality (uniformity, ink absorption, color release)

- Machine compatibility and printing performance

- Roll forming, tightness, and packaging protection

In our factory, we utilize our proprietary sublimation coating technology and rigorous quality control to ensure the supply of stable, high-performance rolls that meet the needs of small businesses and large textile mills.

2.What Sublimation Paper Roll Is — A Technical Explanation

Our roll of sublimation paper looks no different from ordinary paper, but its structure is precisely designed.

2.1 Base Paper (European Sublimation-Specific Base Paper) (Core Layer)

The base paper determines the stability during the printing process:

- Ink Absorption Capacity

- Heat Stability

- Smoothness and Curling Resistance

- Humidity Adaptability

High-quality base paper ensures smooth paper feeding, excellent smoothness, avoids printhead friction, and achieves precise alignment.

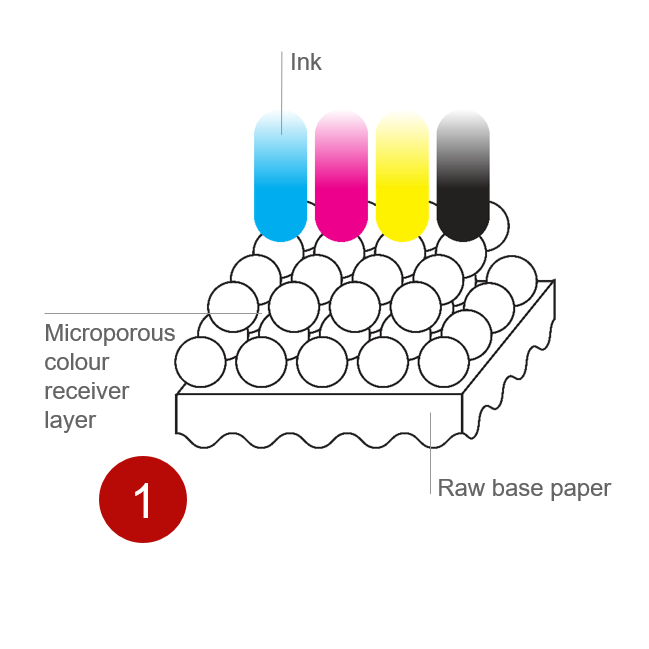

2.2 Coating Structure

The coating is the core of sublimation performance. We use a multi-layer coating structure, including:

- Ink Absorption Layer

- Sublimation Release Layer

- Microporous Structure that firmly locks sublimation ink onto the surface

- Special Quick-Drying Layer for High-Speed Printers

This structure helps improve the following performance aspects:

- Transfer Rate

- Drying Speed

- Color Clarity

- Ink Distribution Uniformity

2.3 Coating Technology

Factory-grade coating quality directly determines the consistency of the paper coating during production.

We employ a fully automated coating process:

- Precision coating head

- Computer-controlled uniformity system

- Real-time viscosity and density monitoring

- High-temperature drying tunnel for stabilizing the coating surface

2.4 Drying Speed and Ink Load

Sublimation paper must meet two key requirements:

- Fast drying (to prevent ink bleeding during high-speed printing)

- Sufficient ink load (for vibrant colors)

- Our coating formulation is optimized to handle both high-ink-volume images and high-speed output.

3.How to Judge High-Quality Dye Sublimation Paper Rolls – Factory Standards

We adhere to, and even exceed, some international standards:

3.1 Transfer Rate (Color Release Efficiency up to 98%)

A high transfer rate means:

- Less ink consumption

- More vibrant colors

- Better penetration into light-colored polyester fibers

We use temperature/pressure controlled printers and spectrophotometers to test transfer rates.

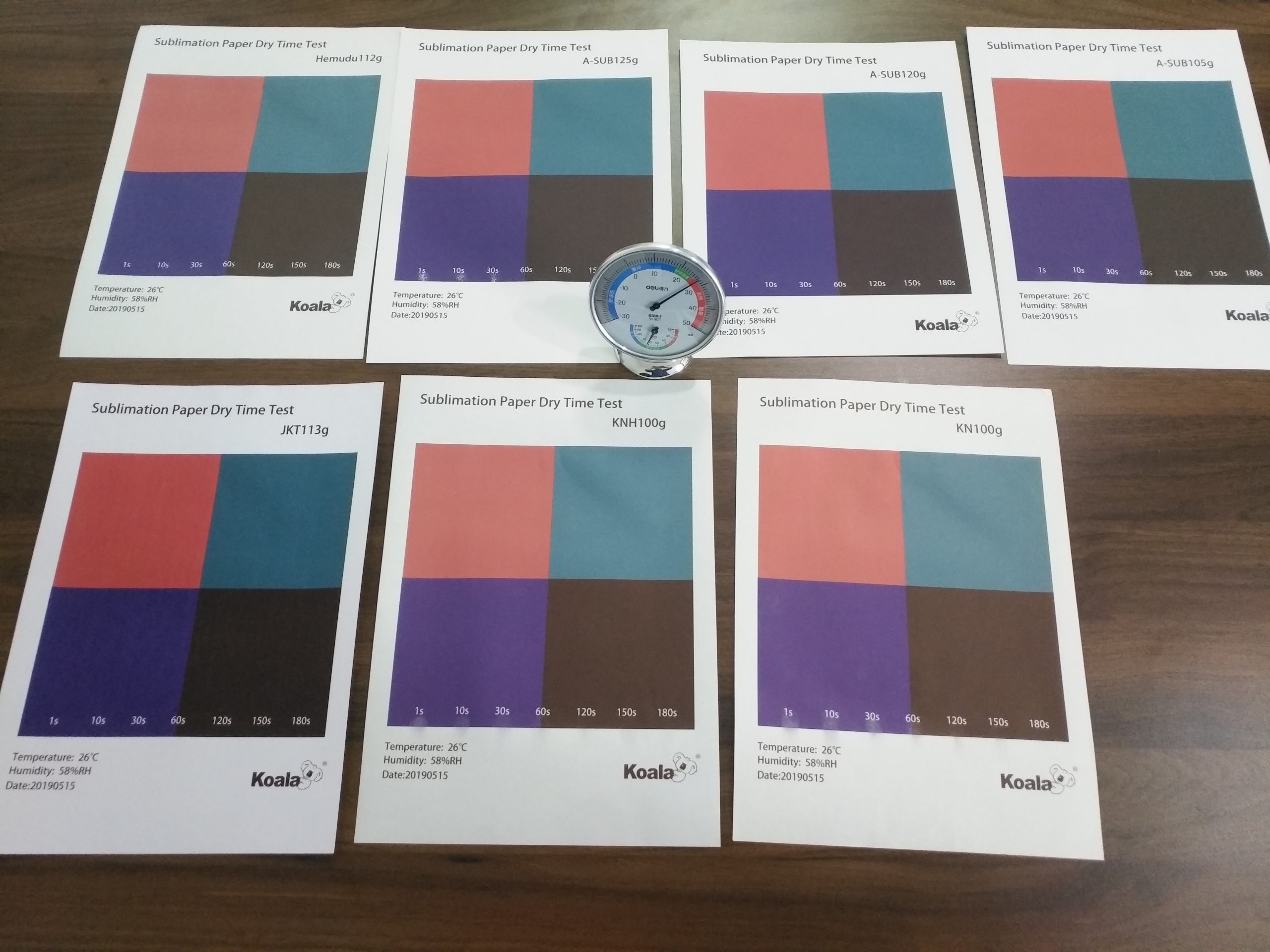

3.2 Drying Speed

Extremely important for the following applications:

- High-speed printers

- High-volume ink printing

- Adhesive paper applications

The microporous structure of fast-drying paper rolls prevents smudging and ghosting.

3.3 Flatness and Curling Resistance

This is a primary concern for customers printing jumbo roll size sublimation.

High-quality paper rolls should possess the following characteristics:

- Maintain flatness during printing

- Avoid edge curling

- Prevent scratching the print head

- Smooth unwinding

Our paper rolls are carefully designed to remain flat even during long production runs.

3.4 Batch Stability

Paper roll traders are most concerned with:

- No color difference between batches

- No coating variation

- No sudden paper jams or feeding issues

We ensure consistency through:

- Automated coating production lines

- Online density testing

- Batch-by-batch ink absorption testing

- Environmental control during storage and packaging

3.5 Printer Compatibility

High-quality dye sublimation paper rolls must be compatible with a variety of sublimation printing systems:Epson, Mimaki, Mutoh, Roland, Ricoh, DGI Sublimation Printer

We have optimized coating smoothness and ink penetration to achieve broad compatibility.

4.Factory Solutions Addressing the Pain Points of B2B Clients such as Trading Distributors

This is precisely where our factory's manufacturing advantages are most fully demonstrated.

4.1 Paper Quality Consistency for Large-Volume Orders

B2B clients require consistent product quality every month.

We ensure quality through the following production methods:

- High-precision coating equipment

- Automated uniformity control

- Strict humidity monitoring

- Professional export-grade packaging

4.2 Printing Speed and Ink Load (High-speed printer models available)

Factories using industrial sublimation printers require paper with the following characteristics:

- Quick-drying

- Wrinkle-resistant

- Capable of handling thick color blocks

We offer:

- High-speed jumbo roll sublimation paper (29gsm / 45gsm)

- Quick-drying models suitable for large-scale textile production

We support:

- Custom width

- Custom roll length

- OEM packaging

- Wholesale and distribution orders

4.4 Export Packaging Protection Measures

To prevent moisture and curling during transportation, We employs the following measures:

- Moisture-proof bags

- Reinforced cartons

- Anti-crushing rings

- Shipping pallet packaging

4.5 Technical Support and Sample Testing

Each customer receives:

- Free samples

- Recommended printing settings

- Heat sealing parameters

- ICC profile (available upon request)

5.Our Product Line

We produce a full range of sublimation paper rolls:

By Grammage (GSM):

- 29gsm Ultra-thin Large Rolls (for industrial high-speed printers)

- 45gsm Lightweight (for soft fabrics and sportswear)

- 50gsm / 55gsm / 70gsm

- 100gsm / 120gsm (for hard objects, mugs, metal, MDF)

By Performance:

- Quick-drying Sublimation Paper Rolls

- Adhesive/Adhesive Sublimation Paper Rolls

- High-speed Industrial Sublimation Paper Rolls

- Large rolls suitable for ultra-wide printing with widths greater than 64 inches (approx. 162 cm)

Customization Options:

- Width: 8.5 inches (approx. 22 cm) → 67 inches (approx. 170 cm) and above

- Length: 100 meters → 1000 meters and above

- Core: 2 inches (approx. 5 cm) / 3 Inch (approx. 7.6 cm)

- OEM Brand Packaging

6.Why Choose Our Factory

Choosing the right sublimation paper roll isn't just about price; it's about partnering with a reliable manufacturer who understands coating science, industrial printing, and quickly addresses customer needs.

We offer:

- Factory direct sales

- Advanced coating technology

- Stability for large volume orders

- Customized production and OEM services

- Professional technical support

Whether you are a distributor, textile mill, or sublimation product manufacturer, we will provide you with a reliable supply chain and consistent quality to help you achieve long-term success.

What makes factory-produced sublimation paper rolls more reliable?

Factory-produced sublimation paper rolls offer consistent coating quality, stable base paper, and batch stability—critical for B2B production and color accuracy.

How do I choose the right GSM for sublimation paper?

29–45gsm is ideal for high-speed textile printing.

70–100gsm suits garments and soft goods.

100–120gsm works best for rigid items like mugs or MDF.

Why is transfer rate important in sublimation paper?

A higher transfer rate delivers brighter colors, reduces ink consumption, and improves fabric penetration—essential for textile factories and sportswear brands.

Does you support OEM and custom roll sizes?

Yes. we provides OEM packaging, customized roll width, roll length, and 2"/3" core options for distributors and industrial customers.

How does you ensure batch stability for large-volume orders?

we uses automated coating lines, online density testing, humidity-controlled warehouses, and multi-stage QC to guarantee consistency across all shipments.