DTF printing technology has emerged as a dynamic force in the printing industry, revolutionizing the way designs are transferred onto various surfaces. This section provides a concise overview of the evolution and significance of DTF printing technology.

Understanding DTF solutions is paramount in today’s market landscape, where businesses seek efficient and versatile printing methods to meet the demands of a fast-paced industry. This introduction delves into the importance of grasping the capabilities and advantages offered by DTF solutions to stay competitive and innovative in the current market scenario.

Understanding DTF Solutions

●What is DTF Printing?

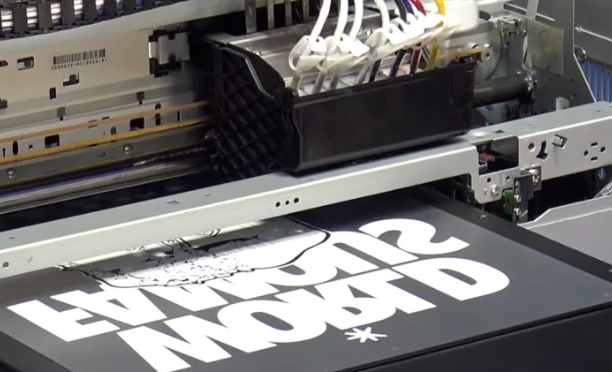

This subsection elaborates on the operational mechanisms and advantages of DTF (Digital Textile Film) technology. DTF technology functions by employing specialized films as carriers for designs, which are printed onto the film using compatible printers. Through a heat press process, these printed films are then transferred onto target materials, ensuring precise adhesion of designs with clarity and sharpness.

The benefits of DTF technology encompass its ability to achieve vibrant color reproduction, rendering designs with rich and vivid hues. Furthermore, DTF excels in capturing intricate detailing, enabling the faithful replication of fine lines and complex patterns. Its versatility in application across various materials, including fabrics, garments, and accessories, underscores its adaptability for a wide array of creative endeavors. These qualities position DTF technology as a preferred choice for those seeking high-quality, detailed, and flexible printing solutions in industries spanning fashion, promotional merchandise, and personalized items.

●Types of DTF Products Available

Films: DTF films are integral to the DTF printing process, serving as the medium for transferring designs onto substrates. These films come in various formulations to meet diverse printing requirements, ensuring high-quality and durable results.

Powder: DTF powder plays a vital role in enhancing adhesion, facilitating precise and clear transfer of designs onto fabrics or other surfaces.

Ink: DTF ink is another essential component in DTF printing, formulated to deliver rich, vivid colors and sharp details, contributing to the overall quality and longevity of the printed designs.

Exploring DTF Services

●DTF Printing Services

DTF printing services are tailored to meet a diverse range of printing requirements, catering to the unique needs of businesses and individuals alike. By offering a versatile approach to printing, DTF services ensure that designs are accurately transferred onto various materials with precision and quality. Whether it’s intricate patterns on textiles or vibrant graphics on promotional items, DTF services excel in delivering customized solutions that align with clients’ specific demands. Koala is a notable player in this field, excelling in providing tailored solutions for businesses of all sizes. Whether a large enterprise or a small-scale operation, Koala offers suitable purchasing plans to meet varied needs.

●Customization Options

The flexibility and customization capabilities inherent in DTF services provide a significant advantage in the realm of printing. Clients can personalize their designs with ease, incorporating unique elements and tailored features to suit their branding or artistic vision. From adjusting colors and sizes to incorporating special effects, DTF services empower individuals and businesses to create bespoke products that stand out in a competitive market. This level of customization not only enhances the visual appeal of printed materials but also allows for a more personalized and engaging end product that resonates with target audiences. Koala has also taken into account the needs of small businesses, individual entrepreneurs, and others by developing A4 desktop solutions, ensuring that a wide range of clients can access and benefit from their services.

Key Questions Addressed

●How Does DTF Compare to Other Printing Methods?

In the realm of textile printing, various methods vie for attention, each offering distinct advantages and considerations. DTF, DTG, and HTV represent three prominent techniques in this landscape.

DTF, characterized by its transfer process using a specialized film and heat press, excels in high-resolution prints and intricate designs. It boasts durability and wash-fastness, making it a preferred choice for long-lasting designs across different fabric types. In terms of cost-effectiveness, DTF shines for medium to large production runs due to its efficiency and ability to deliver top-notch quality prints.

On the other hand, DTG stands out for its direct printing onto garments using specialized inkjet technology. Ideal for detailed and colorful designs on light fabrics, DTG offers a different set of advantages, particularly for smaller production runs. While durable, DTG prints may require specific care during washing to maintain their vibrancy.

HTV, involving the cutting and heat pressing of vinyl designs onto textiles, provides flexibility in design changes without high setup costs, making it a cost-effective option for smaller runs. While offering durability, HTV designs may exhibit signs of wear over time, especially with repeated washings.

In essence, each method—DTF, DTG, and HTV—brings its own strengths and considerations to the table. By understanding the unique features of these techniques—ranging from application methods to durability and cost-effectiveness—decision-makers can effectively choose the most suitable printing approach to meet the specific requirements of their projects.

●What Are the Environmental Impacts of DTF Printing?

Assessing the environmental impacts of DTF printing unveils a critical dimension in the contemporary sustainability discourse, highlighting the eco-friendly advantages that DTF technology can offer.

DTF printing excels in its material efficiency, where the type and quantity of materials used in the process are optimized to minimize waste and reduce environmental impact. By focusing on sustainable sourcing practices and utilizing materials effectively, DTF printing presents itself as a greener alternative in the textile printing industry. The film, inks, and chemicals employed in DTF processes can be selected with sustainability in mind, contributing to a reduced ecological footprint.

●How to Choose the Right DTF Solution for Your Needs?

Choosing the right DTF solution entails a detailed evaluation of a myriad of factors to ensure that the selected option aligns perfectly with specific requirements and objectives.

Material compatibility stands out as a primary consideration when selecting a DTF solution. Different types of fabrics may require specific film and ink formulations to achieve optimal results. Ensuring compatibility between the materials used in the DTF process and the target textiles is essential to guarantee high-quality, durable prints that meet the desired standards.

Moreover, the printing volume plays a crucial role in determining the most suitable DTF solution for a particular project. Businesses with high-volume printing needs may benefit from scalable DTF solutions that offer efficiency and consistency across large production runs. Conversely, individuals or smaller enterprises focusing on low-volume projects may prioritize flexibility and customization options over sheer printing capacity.

In addition, Koala considers both these aspects, catering to a wide range of printing requirements, whether it’s fulfilling large orders with comprehensive services or providing personalized customization options. Koala’s offerings extend to desktop solutions as well, ensuring that businesses and individuals have access to tailored DTF solutions that meet their unique needs. Feel free to reach out for consultations and explore how Koala can address your printing needs effectively.

Cost efficiency is another pivotal factor to weigh when choosing a DTF solution. Evaluating the overall cost of equipment, materials, and maintenance against the projected output and budget constraints is essential for ensuring the economic viability of the chosen printing method. Balancing cost considerations with quality requirements is key to maximizing value and return on investment in DTF printing.

Customization options also play a significant role in the selection process, especially for projects that demand unique designs and personalized touches. Assessing the level of customization offered by different DTF solutions, including the ability to create intricate designs, apply special effects, and accommodate diverse color palettes, can help align the chosen solution with the creative vision and branding objectives of the project.

In conclusion, by carefully considering factors such as material compatibility, printing volume, cost efficiency, and customization options, businesses and individuals can make informed decisions when selecting a DTF solution that best suits their specific needs and objectives. This strategic approach ensures that the chosen DTF solution not only meets technical requirements but also aligns with broader goals of quality, efficiency, and innovation in textile printing endeavors.

Conclusion

In conclusion, DTF printing technology offers a promising avenue for businesses and individuals seeking high-quality and customizable printing solutions. With its vibrant colors, intricate detailing capabilities, and versatile applications, DTF technology presents opportunities for enhanced creativity, efficiency, and sustainability in the printing process. Embracing DTF solutions can lead to innovative and impactful outcomes in the ever-evolving landscape of the printing industry.