DTF printing has emerged as a revolutionary printing technology, offering exceptional versatility, vibrant prints, and durability. With its ability to transfer ink directly from a specialized DTF transfer film onto various surfaces, DTF printing opens up a world of possibilities for customization and creativity.

In this article, we will delve into the intricacies of DTF printing and compare it with two popular printing methods: HTV (Heat Transfer Vinyl) and sublimation printing. By understanding the unique features and benefits of DTF printing, we can explore how it surpasses HTV and sublimation, paving the way for innovative and high-quality printing solutions in diverse industries.

What is DTF Printing?

DTF printing, or Direct-to-Film printing, involves transferring ink from a specialized DTF transfer film onto various surfaces. Unlike traditional methods, DTF printing allows for vibrant colors, intricate designs, and excellent washability. With its versatility, DTF printing can be applied to a wide range of materials, including textiles, ceramics, glass, and more. Compared to other printing methods, DTF stands out for its superior print quality and durability.

Comparison with HTV (Heat Transfer Vinyl)

HTV, or Heat Transfer Vinyl, is a widely used heat transfer method that involves cutting vinyl sheets and applying them to fabrics. While HTV offers convenience and ease of use, it falls short when it comes to achieving outstanding print quality and versatility. In contrast, DTF printing outshines HTV in numerous aspects. DTF printing excels in vibrant color reproduction, allowing for eye-catching prints that truly stand out. The intricate design details achievable with DTF printing surpass what HTV can achieve. Moreover, DTF prints demonstrate remarkable durability, withstanding multiple washes without fading or peeling, ensuring longevity and preserving the quality of the prints over time. The superiority of DTF printing over HTV makes it a preferred choice for those seeking exceptional print quality and longevity in their designs.

Comparison with Sublimation Printing

Sublimation printing is a popular method that involves transferring dye onto specially coated substrates using heat. It is widely recognized for its ability to produce vibrant and long-lasting prints. However, sublimation printing has its limitations, primarily being restricted to polyester-based materials. This limitation significantly narrows down the range of printable substrates.On the other hand, DTF printing offers remarkable versatility, surpassing sublimation printing in terms of the materials it can be applied to. DTF printing allows for printing on a wide range of materials, including cotton, nylon, and even challenging surfaces like ceramics. This versatility opens up a world of possibilities for customization and allows for creative expression on various substrates.In addition to its versatility, DTF printing excels in color vibrancy and detail reproduction. The prints produced by DTF technology exhibit vibrant and vivid colors, capturing the attention of viewers. The intricate details and fine lines in designs are accurately reproduced, resulting in high-quality prints with exceptional clarity.

Key Benefits of DTF Printing

DTF printing offers several key benefits that set it apart from other methods. Firstly, its versatility enables printing on various materials, expanding the possibilities for customization. Secondly, DTF prints exhibit exceptional quality, with vibrant colors, sharp details, and smooth gradients. Moreover, DTF prints are highly durable, demonstrating excellent resistance to fading, cracking, and peeling. This durability extends to washability, ensuring that prints remain vibrant and intact even after multiple wash cycles. Lastly, DTF printing is cost-effective, particularly for small and large-scale productions, as it eliminates the need for costly setup and minimum order quantities.

Applications of DTF Printing

DTF printing finds applications across various industries. In the apparel and fashion industry, DTF printing allows for intricate designs, photo-realistic prints, and customization on a wide range of fabrics. For promotional products, DTF printing offers vibrant branding options on items like mugs, phone cases, and keychains. In the home decor sector, DTF printing enables personalized items such as pillows, wall art, and ceramic tiles. Additionally, artists and designers can leverage DTF printing to bring their creations to life with unmatched precision and color reproduction.

Tips for Successful DTF Printing

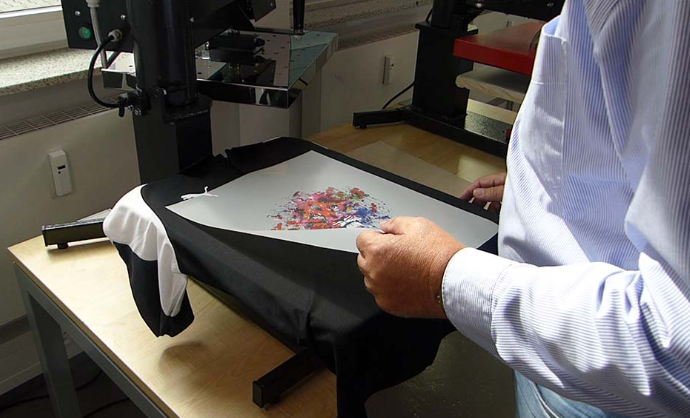

To achieve optimal results with DTF printing, it is crucial to select the right DTF transfer film and ink, properly prepare the printing surface, and follow recommended temperature and pressure settings for the heat press machine. Post-printing curing and finishing techniques also contribute to enhancing the durability and overall quality of DTF prints. Considering the importance of these factors, I highly recommend Koalapaper DTF Solution, a comprehensive and reliable solution provider for all your DTF printing needs. With their expertise and high-quality products, Koalapaper ensures that you have everything you need to achieve outstanding results in your DTF printing projects.

Conclusion

DTF printing has revolutionized the printing industry with its exceptional print quality, versatility, and durability. When compared to HTV and sublimation printing, DTF printing emerges as the superior choice, offering vibrant colors, intricate designs, and the ability to print on various materials. As businesses and individuals seek innovative and high-quality printing solutions, DTF printing is poised to be at the forefront, enabling creativity without limitations.