In today’s dynamic world of printing and design, innovative techniques continue to push the boundaries of creativity and visual impact. UV A&B Film, also known as UV A&B Label, offers a remarkable way to produce crystal-like labels and stickers that captivate the eye with their stunning aesthetics and three-dimensional quality.

With the technology, an A film (printing film), B film (transfer film), white UV DTF ink, UV varnish, and other components are utilized to achieve stunning results. The process involves printing the desired pattern onto the A film and then laminating it with the B film. The transferred design possesses a three-dimensional quality, resembling a crystal, which is why it’s often referred to as a crystal sticker.

In the following sections, we will delve deeper into the fascinating world of UV A&B Label. We will explore the technology behind it, understand the role of its essential components, and discover the myriad applications that UV A&B Labels offer. So, join us on this journey as we unravel the secrets of UV A&B Label and unveil the endless possibilities it presents.

Understanding UV A&B Film

●Detailed Description of the A Film (Printing Film)

The A film, also known as the printing film, is a critical component of UV A&B Film. This specialized film is designed to enable precise and vibrant printing of designs. The A film features an adhesive layer that serves multiple functions. The A film is the printing film, which comes with adhesive. At the same time, the adhesive layer also serves as the ink-absorbing layer. The ink-absorbing properties of the A film contribute to the production of vivid and high-quality printed designs.

●Explanation of the B Film (Transfer Film)

The B film, also referred to as the transfer film, is an essential element in the UV A&B Film printing method. This film plays a crucial role in protecting and transferring the printed design onto the desired surface. The B film acts as a protective layer, shielding the printed pattern from external factors such as smudging, scratching, or fading. Moreover, the B film facilitates the seamless transfer of the design onto the target object. It ensures that the printed design adheres smoothly and accurately, resulting in a professional and visually appealing outcome.

●Step-by-Step Process of printing

The printing process, utilizing the UV A&B films, involves a series of steps to achieve stunning results. Here is a breakdown of the process:

Prepare the A film: Remove the protective paper from the A film, exposing the adhesive side. Place the A film on the flatbed printer, ensuring its proper alignment and securing the four corners on the printer bed.

Print the pattern: Utilizing the printer, print the desired pattern onto the A film. The printing process typically starts with the white ink layer, followed by the CMYK color images, resulting in a vibrant and detailed design.

Laminate with the B film: After printing, cover the printed A film with the B film using a laminating machine. This step ensures the protection of the printed design and prepares it for transfer onto the target object.

Cut the image: Use cutting equipment or scissors to carefully cut along the edges of the printed image.

Peel and transfer: Take out an individual sticker, peel off the A film from the back of the design, and apply the sticker to the desired surface. Press firmly with fingers to ensure proper adhesion, and then peel off the B film. The transferred UV sticker now exhibits a three-dimensional, crystal-like appearance.

Advantages and Applications of UV A&B labels

●Advantages of UV A&B labels

UV A&B stickers offer several advantages that make them a popular choice for businesses and individuals seeking visually stunning and durable designs. Here are some key advantages of UV A&B labels:

Vibrant and Bright Patterns

UV A&B Film produces stickers with vivid and eye-catching patterns. The ink used in the printing process results in vibrant colors that make designs stand out.

Versatility on Various Surfaces

One of the remarkable advantages of UV A&B labels is their ability to adhere to a wide range of hard materials. Whether it’s glass products, leather, wood, metal, acrylic, or paper packaging, UV A&B labels can be applied to these surfaces with ease. This versatility allows for creative applications in diverse industries.

Compatibility with Challenging Surfaces

UV A&B labels prove their versatility by being compatible with various surface textures. Whether the surface is flat, smooth, frosted, or curved, UV A&B labels can conform to these challenging surfaces. They can even be applied to the interiors of cups, expanding the possibilities for unique and personalized designs.

Scratch and Wear Resistance

Once transferred onto the surface of hard materials, UV A&B labels exhibit excellent resistance to scratching and wear. This durability ensures that the designs remain intact and visually appealing, even in high-contact or demanding environments.

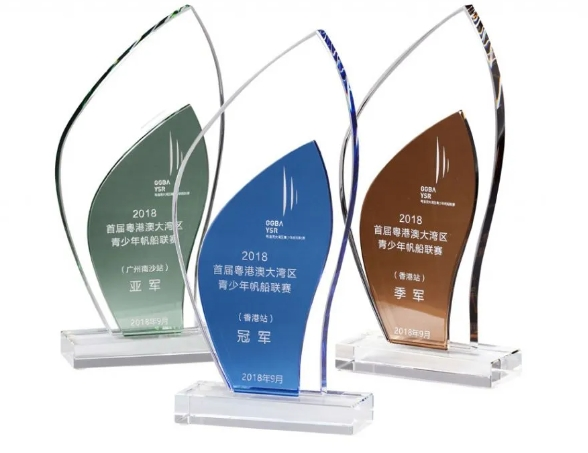

Three-Dimensional Effect Resembling Crystal

UV A&B labels possess a distinct three-dimensional effect that resembles the appearance of crystal. This unique quality adds depth and visual intrigue to the designs, making them captivating and attention-grabbing.

●Applications of UV A&B Label

UV A&B labels offer versatile applications, allowing patterns to be effortlessly transferred onto a wide range of hard materials. These stickers find use on surfaces such as glass products, leather, wood products, metal, acrylic, paper packaging, and more. Their adaptability makes them suitable for various applications, including but not limited to tea boxes, wine bottles, cosmetics, labels, and other creative endeavors.

Comparison with Other Labels

When considering labeling options, it is essential to compare UV A&B Labels with other types of labels available in the market. Here are some key points to consider when comparing UV A&B Labels with other labeling methods:

●Print Quality

UV A&B Labels excel in print quality, offering vibrant and visually striking patterns. The UV A&B Labels printing process allows for precise color reproduction and intricate details, resulting in high-definition designs. In comparison, other labeling methods may not achieve the same level of sharpness and color intensity.

●Surface Compatibility

UV A&B Labels demonstrate exceptional compatibility with various hard materials, including glass, leather, wood, metal, and acrylic. They can adhere to challenging surfaces such as frosted or curved textures. In contrast, some other labeling methods may have limitations regarding the types of surfaces they can be applied to, restricting their versatility.

●Durability

UV A&B Labels exhibit excellent durability after being transferred onto the surface of hard materials. They are resistant to scratching and wear, ensuring that the designs remain intact over time. In comparison, some other labeling methods may be more prone to damage or fading, particularly when exposed to external factors.

●Customization and Personalization

UV A&B Labels offer extensive customization options, allowing for personalized designs and unique branding opportunities. The versatility of UV A&B Labels enables businesses and individuals to create bespoke labels that reflect their style and identity. Other labeling methods may have limitations in terms of customization, as they may rely on pre-made templates or limited design options.

●Visual Effects

UV DTF stickers possess a distinct three-dimensional effect, resembling the appearance of crystal. This visual depth adds an extra dimension to the designs, making them visually captivating. In contrast, some other labeling methods may have a flatter or less dynamic visual impact.

It is important to evaluate these factors and consider the specific requirements of your labeling project when comparing UV DTF stickers with alternative labeling methods. Ultimately, UV DTF stickers offer exceptional print quality, surface compatibility, durability, customization options, and unique visual effects, making them a compelling choice for various labeling applications.

Tips: While UV A&B Label offer numerous advantages, it is worth noting that they may be relatively more expensive.

Reasons to Choose Koalapaper UV A&B Film

Koalapaper has established itself as a trusted brand in the consumables industry, offering a wide range of products such as photo paper, stickers, and transfer paper. Here are several reasons why Koalapaper UV A&B film is a reliable choice:

With a long-standing presence in the industry, Koalapaper has accumulated extensive experience and expertise. Their diverse product portfolio showcases their commitment to meeting various market needs. This track record of delivering quality materials has earned Koalapaper the trust of numerous customers.

As a reputable company, Koalapaper offers brand assurance and has established partnerships with multiple companies. This wide network of collaborations further enhances Koalapaper’s credibility and reliability. Choosing Koalapaper means opting for a trusted and reputable supplier.

Koalapaper operates multiple production lines, ensuring high production capacity. This allows them to meet the demands of customers efficiently, even during peak periods. The ability to scale production effectively demonstrates Koalapaper’s dedication to fulfilling customer requirements.

Quality assurance is a key focus for Koalapaper. Their UV A&B film undergoes rigorous testing and inspection processes to ensure consistent performance and adherence to industry standards. By maintaining strict quality control measures, Koalapaper delivers products that consistently meet or exceed customer expectations.

Koalapaper has built a loyal customer base by prioritizing customer satisfaction. Through reliable product offerings, excellent customer service, and the cultivation of long-term relationships, Koalapaper has gained the trust and loyalty of its customers.

By choosing Koalapaper UV A&B film, customers can benefit from their extensive experience, diverse product range, brand assurance, high production capacity, quality assurance, and commitment to customer satisfaction. Koalapaper continues to be a reliable and trusted choice for UV A&B film and other consumables in the industry.

Conclusion

In summary, UV A&B film is a powerful tool for creating visually appealing and durable labels on various hard materials. Whether you are in the packaging industry, cosmetics, or any other field requiring high-quality labeling, UV A&B film offers the versatility and superior performance you need.

Partnering with Koalapaper ensures you have a reliable supplier that understands your needs and delivers exceptional UV A&B film products. Make the smart choice and experience the benefits of Koalapaper’s expertise and commitment to customer satisfaction.