The manufacturing of inkjet sticker paper is a journey of transformation that involves a symphony of intricate processes. Understanding it will help you wholesale it a lot. So, How do we manufacture inkjet sticker paper?

Manufacturing inkjet sticker paper involves a multifaceted process that begins with raw materials and progresses through various intricate stages, including cutting, and quality checks. The end result is a reliable and visually captivating product that serves as a versatile canvas for creativity.

Now, join us on a journey through the layers of inkjet sticker paper and the precision of its production process.

The composition of inkjet sticker paper involves not only the adhesive layer but also the crucial components that form the facestock, liner and so on. Understanding the intricate structure of these layers provides insight into the paper’s durability, printing capabilities, and overall performance.

2.1. Facestock

The facestock is a composite of three essential layers: top-coating, face material, and primer. These layers work in harmony to create a versatile and effective surface for printing, adhesion, and protection. Within the realm of facestock, two common material categories emerge: paper-based substrates and film-based substrates.

Paper-based substrates offer a classic appearance and are suitable for a wide range of applications. They are particularly popular for indoor uses, providing a traditional aesthetic with a writable surface. On the other hand, film-based substrates offer enhanced durability and are often chosen for outdoor applications, as they resist moisture, tearing, and UV exposure more effectively.

2.2.Top-Coating

The top-coating layer serves as a functional enhancement that directly impacts print quality. It improves the paper’s print adaptability, allowing ink to adhere smoothly and vividly. This coating layer plays a significant role in achieving vibrant colors, sharp details, and high-resolution images. Additionally, the top-coating can offer protective qualities, guarding the printed design against environmental factors and physical wear.

2.3.Primer

The primer layer, like the top-coating, is a functional layer that enhances the properties of the adhesive and the face material. It acts as a bonding agent, facilitating the strong integration of the adhesive with the face material. The primer can also serve as a barrier layer, preventing unwanted interactions between the adhesive and the face material, thus ensuring adhesive performance and sticker integrity.

2.4.Adhesive layer

The adhesive layer is what makes inkjet sticker paper stick to different surfaces. It’s a critical component that demands careful consideration. Adhesives serve a dual purpose: they ensure the appropriate bond between the facestock and liner, while also guaranteeing strong adhesion to the substrate upon application.

There are two main types of adhesive layers for inkjet sticker paper on the market: Water-based adhesives and Oil-Based Adhesives.

Water-based adhesives offer remarkable versatility and easy removability, making them well-suited for applications that require temporary adhesion. These adhesives are designed to create a strong initial bond while allowing the sticker to be easily peeled off without leaving any residue behind. This characteristic is particularly valuable when stickers need to be repositioned or replaced, ensuring a clean and hassle-free removal process.

In contrast, oil-based adhesives are known for their exceptional permanence. These adhesives establish a robust and enduring bond, making them ideal for applications that demand long-lasting adhesion. Oil-based adhesives provide resilience against environmental factors such as moisture, temperature fluctuations, and exposure to various chemicals. This level of durability ensures that your stickers remain firmly affixed, even in challenging conditions.

In addition, the permanent label and the removable label have to do with the primer, but also with the glue.

Permanent labels, equipped with solvent-based adhesives, establish a tenacious bond that is designed to withstand harsh environments. They are ideal for outdoor applications, products subjected to frequent handling, or surfaces that are exposed to moisture and other external factors. These labels ensure that your designs remain intact and legible over an extended period, maintaining the integrity of your brand and communication.

On the other hand, removable labels, which utilize water-based adhesives, offer the advantage of flexibility and easy removal. These labels are perfect for scenarios where temporary adhesion is required. For instance, in promotions, events, or labeling where stickers need to be repositioned or replaced without causing any damage to the substrate. Their ability to adhere securely while allowing effortless removal makes them a preferred choice when adaptability is paramount.

As you navigate the realm of inkjet sticker paper, the choice of adhesive plays a pivotal role in determining how your stickers perform in the real world. Whether you opt for the steadfast permanence of solvent-based adhesives or the convenience of water-based adhesives, your decision should align with the specific requirements of your applications. By understanding the characteristics and differences between these adhesive types, you can confidently select the adhesive that ensures your designs adhere securely, communicate effectively, and stand the test of time. The adhesive not only bonds the layers of the sticker paper but also forms the bridge between the sticker and the surface it adheres to, delivering the desired level of attachment while offering easy removal when needed.

2.5.Liner

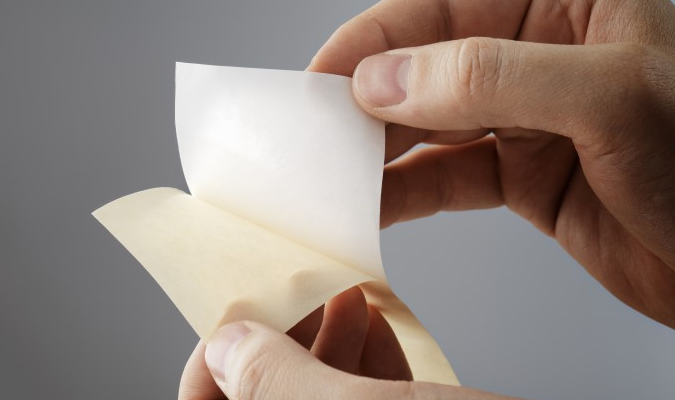

The liner, also known as the backing, serves as the support for the adhesive layer and facestock. It’s designed to be non-adhesive, ensuring that the inkjet sticker paper can be easily peeled off and applied. The liner consists of two integral parts: the release liner and the base paper.

The release liner is a critical component that allows for the smooth application of the inkjet sticker paper. It is typically coated with a release agent, commonly organic silicon oil, which imparts a non-stick quality to its surface. This ensures that the adhesive remains firmly attached to the face material until application, allowing for seamless peeling and sticking.

The base paper forms the foundational layer of the liner. It provides structural support to the release liner and ensures that the entire sticker paper maintains its integrity during handling, storage, and application. The base paper’s surface remains non-adhesive, serving as a separation layer that prevents premature adhesion before the intended application.

In essence, the intricate combination of top-coating, face material, primer, and liner ensures that inkjet sticker paper is equipped to meet various demands. Whether you’re seeking enhanced print quality, improved adhesive performance, or reliable durability, each layer plays a role in delivering a sticker paper that excels in its applications. The meticulous design of these layers underscores the complexity and versatility of inkjet sticker paper, allowing it to seamlessly integrate into your branding, labeling, and creative endeavors.

In terms of materials, Koala Inkjet Sticker Paper uses high quality materials, not lacking many imported materials. This ensures quality and beauty at the same time.

3.Precision Cutting and Sizing

Precision cutting and sizing epitomize attention to detail. Cutting machinery, guided by advanced technology, skillfully transforms coated sheets into perfectly sized sticker paper. This precision ensures that each sheet adheres to exact specifications, providing a seamless canvas for creative expression.

In addition, Koala’s exceptional cutting capabilities stem from our extensive production capacity and diverse machinery resources. With the flexibility to accommodate customized sizing requests, we encourage open communication with our clients. We are committed to meeting the specific requirements of our partners, ensuring that their needs and expectations are not just met but exceeded.

4.Quality Control and Assurance

Quality control is a continuous thread woven through every stage of production. Stringent checks ensure that texture, color vibrancy, and print performance align with industry standards. By adhering to these rigorous measures, manufacturers guarantee that each sheet meets the highest quality benchmarks.

5.Product Compatibility

Inkjet sticker paper’s performance is not solely reliant on its manufacturing process; compatibility with various inkjet printers is paramount. Manufacturers engineer sticker paper to interact harmoniously with an array of printers, resulting in reliable and vibrant printing outcomes.

6.Environmental Responsibility

Beyond quality and performance, environmental responsibility finds a place in the manufacturing process. Adherence to sustainable practices, responsible material sourcing, and eco-friendly coatings reflect a commitment to both quality and the planet.

7.Conclusion

In conclusion, the journey from raw materials to finished inkjet sticker paper is an intricate dance of technology, craftsmanship, and quality assurance. As consumers, we are the beneficiaries of this meticulous process, reaping the rewards in the form of reliable, vibrant, and visually captivating sticker paper.

Understanding the nuances of this journey empowers you to make informed purchasing decisions that align with your creative goals and printing projects. Whether you require permanent or removable labels, need indoor or outdoor durability, or seek vibrant print quality, the careful consideration of inkjet sticker paper construction, adhesive type, and liner design ensures that your stickers excel in their intended applications.

At Koala, we take pride in our commitment to premium raw materials, precision cutting, and environmental responsibility. We understand that each creative endeavor is unique, and our dedication to collaboration and customization allows us to tailor inkjet sticker paper to your specific needs.If you are interested in Koala Inkjet Sticker Paper after reading this article, please feel free to contact us by clicking on the Koala official website.