Table of Contents

ToggleIntroduction

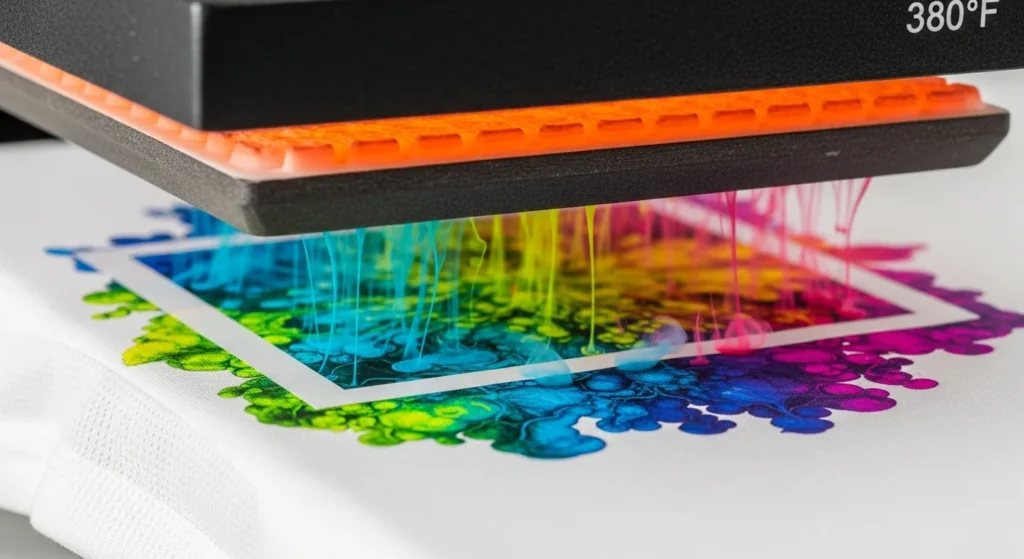

Sublimation printing is becoming increasingly common in areas such as garment manufacturing, sportswear production, textiles, home decor, and personalized customization. While this printing method is quite mature,many users—especially professional garment manufacturers—face a common challenge: paper shifting and ghosting during the sublimation transfer process. This problem is particularly severe when transferring onto elastic or delicate fabrics.

This is why Sticky sublimation paper (also known as Tacky sublimation paper) has become the perfect solution. This type of sublimation paper doesn't rely solely on heat and pressure, but also features a special adhesive coating that helps our customers prevent pattern shifting and ghosting during actual production.

In this comprehensive guide, we will explain:

- What tacky sublimation paper is and how it works

- Why adhesive stability is more important than simple tackiness

- How Koala tacky sublimation paper performs in real-world factory Environments

- Why sheet-size tacky sublimation paper is a significant competitive advantage

- Who should choose roll or sheet size adhesive sublimation paper

- And which practical applications are best suited for tacky sublimation solutions

Whether you are a printing novice, a large studio owner, or an industrial-scale factory/manufacturer, this guide will help you understand whether tacky sublimation paper is the right choice for your production.

What is tacky sublimation paper?

Tacky sublimation paper is a transfer paper treated with a special coating containing a heat-activated adhesive. During the sublimation process, when heat and pressure are applied, the adhesive in the coating becomes tacky, helping the paper adhere firmly to light-colored polyester or elastic fabrics/thin materials. This prevents the sublimation paper from shifting during the ink transfer to the fabric fibers.

Compared to regular sublimation paper:

| Regular Sublimation Paper | Adhesive sublimation paper |

| No adhesive layer | Built-in tacky coating |

| Easily affected by movement | Designed to stay in place |

| Potential ghosting risk | Strong anti-ghosting performance |

| Best for simple/apparel prints | Best for precision + difficult fabrics |

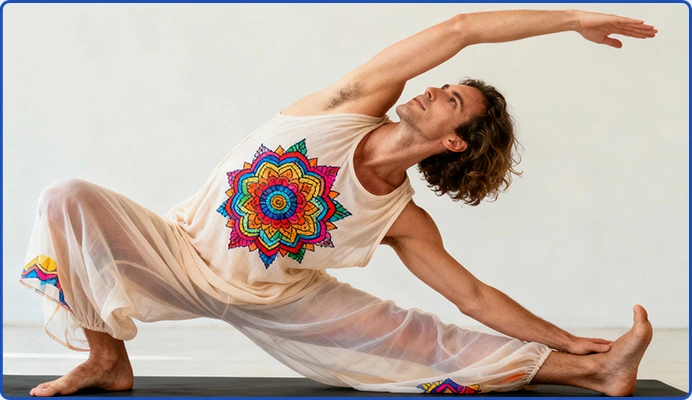

Due to this unique characteristic, adhesive sublimation paper is widely used in the following areas:

- Sportswear manufacturing

- Printing on fashion apparel and leggings

- Elastic fabrics such as polyester and spandex blends

- Large-format image printing requiring high precision

- Professional production requiring extremely high consistency for each printed item

For many apparel companies transitioning from small-scale sublimation printing studios to mass production, Sticky sublimation paper is one of the upgrade options.

Why is adhesion so important in sublimation printing?

Even when using heat-resistant tape to secure the paper and fabric,visible pattern ghosting can occur. During the heat transfer process,pressure, thermal expansion, or fabric elasticity can cause slight movement on the fabric surface.

This can lead to the following problems:

- Pattern misalignment

- Blurred image edges

- Ghosting

- Shadowing

- Wasted fabric and labor time

In a real-world sales environment, these are not minor flaws—they can lead to mass returns. A rejected sweatshirt, a batch of scrapped garments,or a roll of wasted fabric can all result in financial losses, customer complaints, and increased costs.

Therefore, for factory-level sublimation printing, strong and reliable paper adhesion is not optional, but essential.

Adhesion and Adhesion Stability – Two Completely Different Concepts

Many users believe that as long as the sublimation paper sticks, that's sufficient. However, actual production processes show that

what's more important is:

Adhesion Stability

This means that the sticky sublimation paper must:

- Adhere firmly during printing

- Maintain adhesion during handling

- Remain reliable during storage

- Perform stably during the heat press process

Unfortunately, many sticky sublimation papers on the market only have short-term adhesion (1-3 days). If the printed paper requires better

storage conditions, otherwise the adhesion will weaken or even disappear.

This can lead to:

- Paper detachment before heat pressing

- Paper falling off after storage

- Misalignment during subsequent transfer processes

In modern printing manufacturing, pre-printing and batch-based streamlined production are becoming increasingly common, making this a crucial flaw.

7-Day Adhesive Stability — Tested in Real-World Production Environments

To evaluate real-world performance, we tested our Tacky Sublimation Paper.The tests simulated actual production processes, not just laboratory conditions.

Testing Procedure

Sublimation designs were printed onto the adhesive sublimation paper.The printed paper was stored, not immediately heat-transferred.Heat transfer was performed after a period of storage.

Test Results

Even after 7 days of storage, Koala Tacky Sublimation Paper maintained

its adhesive stability:

- Strong and reliable adhesion

- Complete contact with the fabric

- Resistant to peeling

- Stable under high temperature and pressure

This real-world production advantage allows garment manufacturers to:

- Pre-print in advance

- Handle large orders more flexibly

- Maintain efficient production schedules

- Reduce waste and rework rates

This reliability is crucial for industrial and professional sublimation printing environments.

Strong Adhesion + Easy Release — Balanced Bonding

Regarding tacky sublimation paper, a common concern is whether the strong adhesive will damage the fabric or make it difficult to peel off

the paper. In fact, if the adhesive is too strong, it may:

- Stretch delicate fabrics

- Damage the fiber surface

- Leave sticky residue

- Reduce production efficiency

We have specifically developed this Sticky sublimation paper to ensure balanced adhesion:

During heat pressing:

- The paper is firmly fixed

- The fabric does not easily shift

- Effectively prevents ghosting

After heat pressing:

- The paper peels off easily

- Does not tear

- Does not damage the fabric

- Leaves no residue

This balanced adhesive force makes our Sticky sublimation paper not only strong and reliable, but also comfortable and safe to use, and helps improve production efficiency.

Transfer Performance – Secure Adhesion, Vibrant Colors

Some users worry that the adhesive coating might negatively affect ink transfer results. However, our sublimation paper is carefully designed to ensure high-quality printing results.

Our adhesive sublimation paper offers the following advantages:

- Excellent transfer efficiency

- Rich and vibrant color output

- Stable black density performance

- Sharp edge details

- Consistency even with high ink volume designs

This means users don't have to choose between:

- Stability

- Print quality

They can have both – secure adhesion and professional-grade color performance.

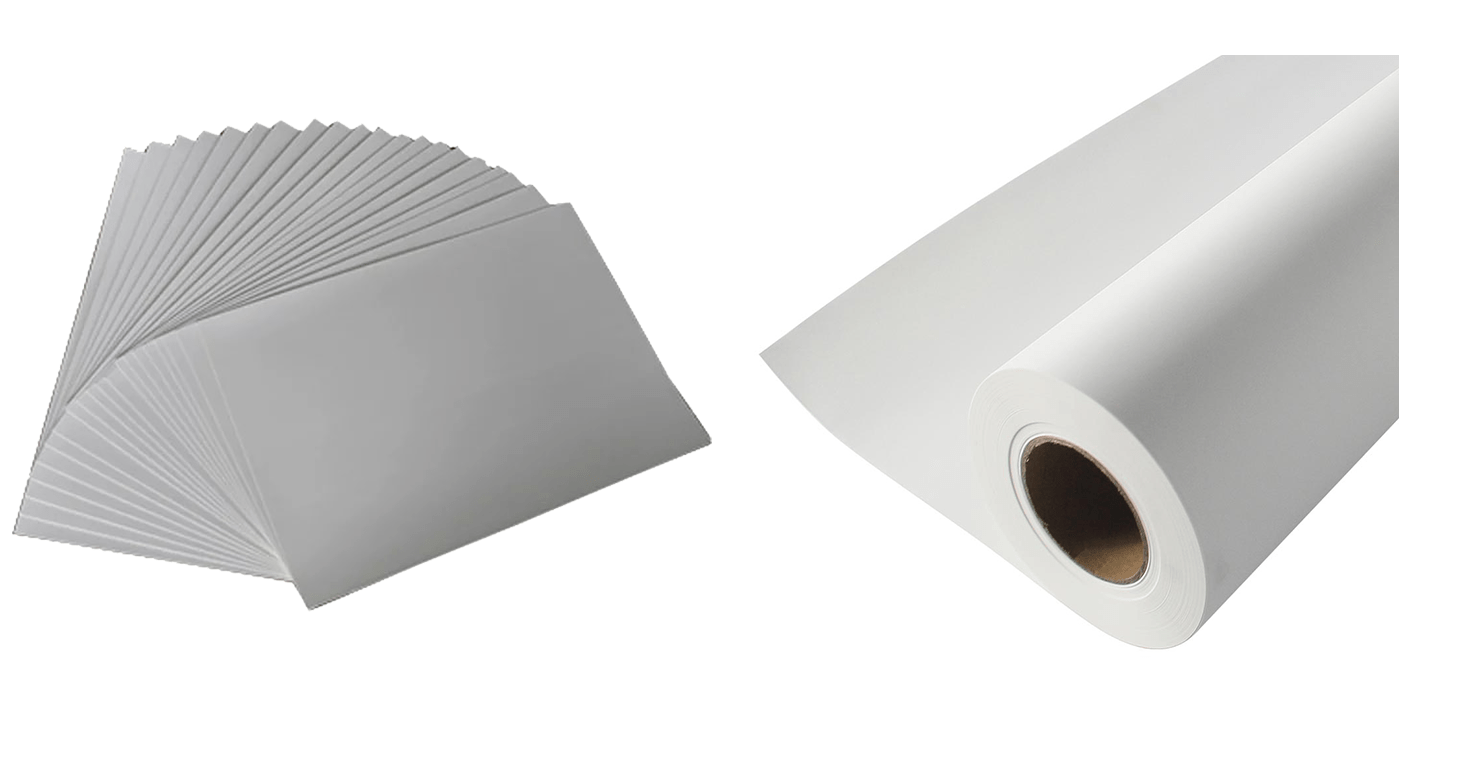

Roll vs. Sheet Sizes – Offering Users More Choices and Flexibility

Many products in the adhesive sublimation transfer paper market are only available in roll form. By offering both roll and sheet sizes Of sublimation paper, we expand the application range for apparel/textiles, allowing customers to choose the most suitable size specifications based on their business needs.

When Rolls Are the Right Choice?

Roll format is especially suitable for:

- Large-format sublimation printers

- Industrial and continuous printing

- Full-width garment panels

- High-volume factory environments

Roll tacky paper improves efficiency in mass production and large fabric handling.

⭐⭐ Adhesive Sublimation Paper Sheet Size — Our Strongest Competitive Advantage

Our adhesive sublimation paper sheets meet the needs of studios, custom workshops, printing companies, and small to medium-sized production users.

Advantages of Sheet-Sized Adhesive Sublimation Paper

- ✔ No cutting or trimming required

- ✔ Easier alignment of logos and small designs

- ✔ Faster heat press workflow setup

- ✔ More convenient for operators

- ✔ Easier storage and handling

Perfectly suited for:

- Custom apparel studios

- Small printing businesses

- Brand personalization workshops

- Sublimation paper retailers and distributors

- On-demand production environments

Many adhesive sublimation paper suppliers do not offer sheet sizes.Therefore, sheet-sized adhesive sublimation paper is one of our strongest and most practical differentiating advantages.

Which customers should choose sheet size Tacky sublimation paper?

Sheet size is ideal for the following users:

- Heat press users

- Desktop sublimation printer users

- Small-batch garment manufacturers

- Logo printing professionals

- Personalized gift suppliers

For these users, this size can significantly improve production efficiency, reduce operational complexity, and minimize the risk of defects.

Conclusion – Choosing the Right Tacky Sublimation Paper

When choosing the best tacky sublimation paper, consider the following factors:

1️⃣ Adhesive Stability

It's not just about tackiness – reliability during storage and handling is crucial.

2️⃣ Secure Adhesion + Easy Release

Prevents shifting while ensuring safe and easy removal.

3️⃣ Available in Roll and Sheet Formats

Rolls are suitable for industrial use.Sheets are suitable for flexible production needs.

We are committed to providing stable, professional sublimation solutions for practical production, designed to address real-world manufacturing challenges and evolving business needs.

Does tacky sublimation paper leave residue?

No. Our tacky sublimation paper offer secure adhesion with clean release and no residue.

Can printed tacky sublimation paper be stored?

Yes. Our testing proved adhesion remain stable even after up to 7 days of storage.

Is tacky sublimation paper only for factories?

No. With sheet size tacky sublimation paper, even small studios can enjoy professional-level stability.

Does adhesive affect color transfer?

No. We maintain strong transfer performance with vivid colors and consistent density.

Which fabrics benefit most?

Best for:

Polyester

Polyester + Spandex

Sportswear materials

Stretch fabrics