Table of Contents

ToggleIntroduction: Why Real DTF Film User Feedback is More Important Than Stated Specifications

When users search for "DTF film roll test" or "DTF film roll review," they are not new to DTF printing. Most of them already own a DTF printer, DTF ink, and DTF powder, and have tried at least one manufacturer's dtf film, encountering problems with poor transfer results or unstable film performance during actual use/production.

Common user questions include:

"My DTF printer is working normally, but the transfer results are inconsistent."

"The same design produces different results when printed at different times."

"Is this a problem with the ink, the powder, or the film?"

In the actual DTF transfer printing process, the stability of the PET film has a far greater impact on the transfer results than other consumables.

This article, written entirely from the user's perspective and based on common user feedback, test comparisons, and our factory's actual production experience, aims to help users understand the factors they truly need to consider when choosing DTF film rolls.

What are the main user groups for Direct to Film (DTF) printing currently on the market?

To make the evaluation more valuable, DTF Solutions user feedback can be broadly categorized into the following four types:

1.Small-scale garment printing and customization studios

- Daily production: 20-100 garments

- Focus on flexibility, easy peeling, and low waste rate

- Typically use 30cm or 60cm DTF Transfer Film Rolls

2.Print-on-demand (POD) and online e-commerce sellers

- Frequent design changes

- Require stable colors and consistent transfer effects for DTF film for printing

- Highly sensitive to/concerned about failure rates/defective rates

3.Garment factories

Garment factories

- Large-scale production

- Prioritize efficiency, reliable peeling, and long-term stability

- Mainly use 60cm, 100cm, or 120cm DTF Film Rolls

4.Promotional product and event merchandise manufacturers

- Short delivery cycles

- High production volume

- Require film stability to avoid rework

Despite varying production scales/needs, their feedback is surprisingly similar.

Most Common DTF Film Roll Problems - Based on User Feedback Collected from Our Factory

Problem 1: DTF Ink Fails to Transfer Completely, Leaving Residue

DTF Ink Fails to Transfer

User Feedback:

"After heat pressing, some areas appear faded or incomplete, and there is ink residue on the film."

User's Initial Suspected Causes:

Ink quality, ICC profile, or heat press temperature.

Test Results Show:

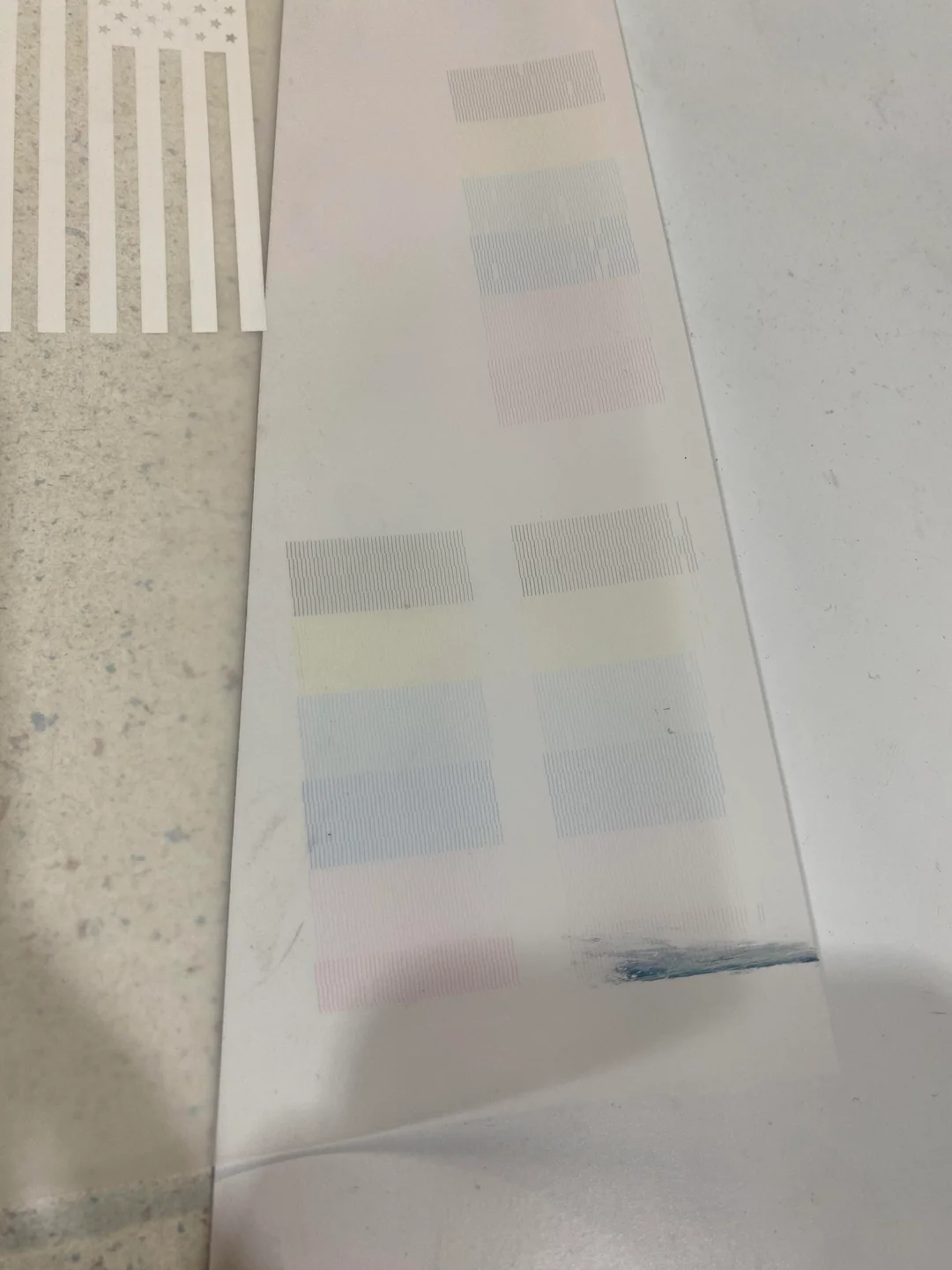

In many cases, the problem stems from uneven coating on the DTF film or poor base film quality.

If the cause is the coating:

- Uneven ink absorption

- Uneven drying

- Lack of sufficient ink adhesion

Then, the transferred image will show missing or lighter areas, especially in gradient transitions and fine details.

Problem 2: Uneven DTF Powder Adhesion

User Feedback:

"The powder adhesion is uneven, resulting in blank areas."

This problem is often mistakenly attributed to:

- Poor powder quality

- Incorrect powder shaking method

Actual Cause:

Insufficient surface properties or electrostatic imbalance of the Direct to Film.

High-quality DTF film rolls (our Koala DTF film) have the following characteristics:

- Uniform electrostatic properties

- Consistent coating roughness

- This ensures stable powder adhesion across the entire printed area of the design.

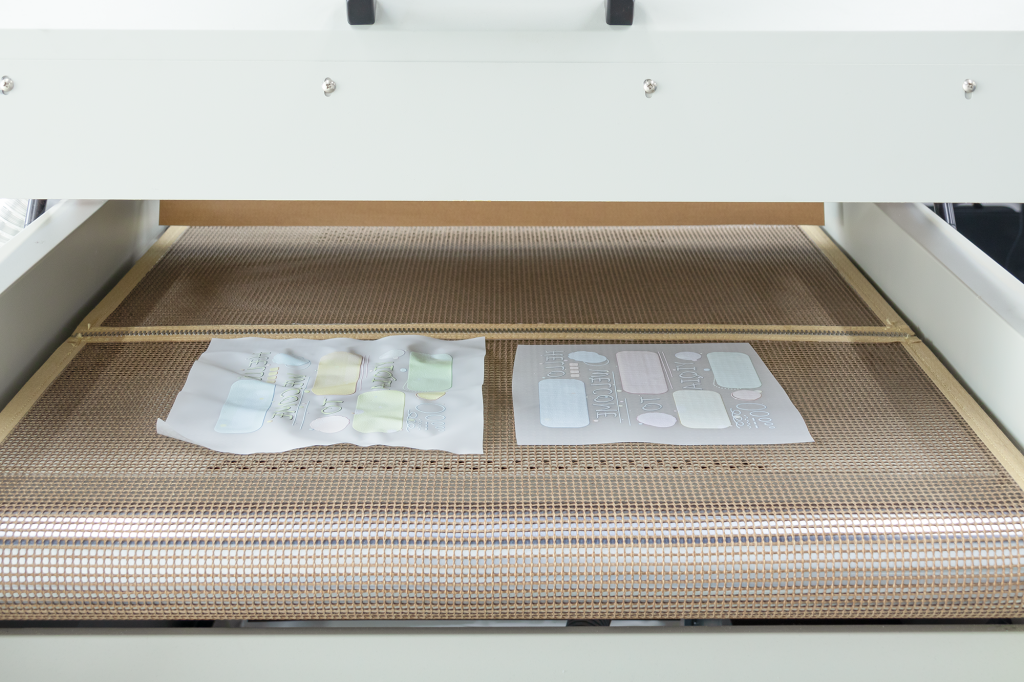

Problem 3: Film roll curling or shrinking during heating

User feedback:

"The film curls during the curing process, affecting production."

This situation is common in:

- Automatic powder coating machines

- Long production runs

Root cause:

Poor quality PET base film or improper tension control during production.

Once curling occurs:

- Alignment becomes difficult

- Powder distribution is uneven

- Production speed decreases significantly

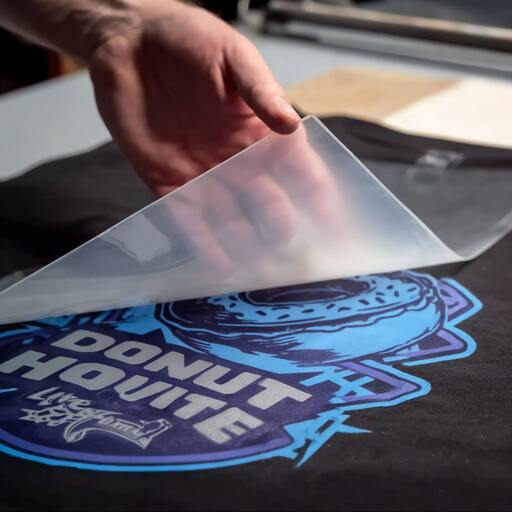

Problem 4: Heat Transfer Film is Difficult to Peel or Tears Easily

User Feedback:

"Sometimes the heat peeling works, sometimes the film tears."

Inconsistent peeling performance is one of the biggest problems for users.

Possible causes include:

- Unstable release layer

- Inconsistent peeling temperature tolerance

- Peeling type incompatible with the user's workflow

In a production environment, peeling reliability directly impacts:

- Labor efficiency

- Rework rate

- Customer satisfaction

User Test Results: Same DTF Printer, Different DTF Film Rolls for Printing

To test the performance of different DTF films, many users conduct simple but effective tests:

- Using the same printer

- Using the same ink

- Using the same powder

- Using the same heat press settings

Observed results from user testing

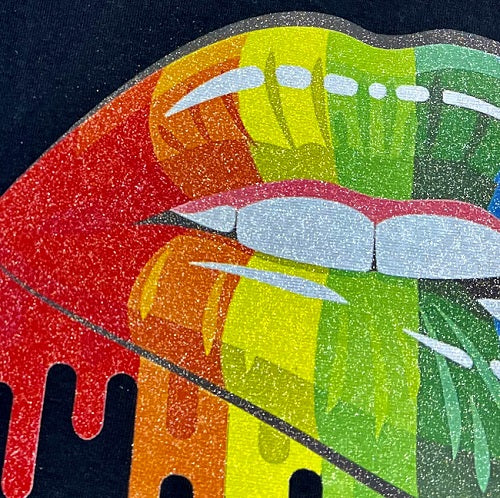

| Test Item | Budget Film | Mid-Range Film | Stable Industrial Koala Film |

| Ink Absorption | Uneven | Acceptable | Consistent |

| Powder Adhesion | Patchy | Mostly stable | Uniform |

| Edge Sharpness | Blurred | Clear | Sharp |

| Peel Stability | Inconsistent | Occasional issues | Reliable |

| Wash Durability | Fading | Moderate | Long-lasting |

Users frequently report that simply changing the film, without altering any other variables, can significantly improve the transfer results.

Why do some DTF film rolls fail in actual production?

From a user's perspective, film failure is usually due to the following reasons:

- Uneven coating thickness

- Lack of static control

- Unstable PET substrate

However, in actual production:

- Humidity changes

- Long-term printing

- Automated equipment

All these factors amplify the problems and defects of DTF PET film.

This is why films with seemingly similar parameters on the specifications sheet can yield drastically different results in a real production environment.

How Users Adjust Their Direct-to-Film (DTF) Film Selection After Testing

After experiencing failures, users change the way they select DTF film rolls.

They no longer consider price as the sole determining factor, but instead consider multiple factors:

- Transfer success rate

- Peeling reliability

- Color density consistency

- Reduced waste

- Machine compatibility

Users often say:

"If we can avoid repeated printing, a slightly more expensive DTF film is actually more cost-effective in the long run."

User Feedback on DTF Film Roll Sizes and Applications

Film size also impacts user satisfaction.

30cm DTF Roll:

- Flexible and convenient

- Less waste

- Ideal for small studios and print-on-demand (POD) sellers

60cm DTF Roll:

- The most balanced option

- Suitable for everyday production

- The preferred choice for garment manufacturers

100-120cm DTF Roll:

- High efficiency

- Designed for industrial production processes

- Best suited for mass production

Many users report that using the appropriate size reduces operational problems and film waste, thereby improving overall efficiency.

How can distributors/traders test the effectiveness of DTF film rolls before placing large orders?

Experienced commercial users recommend:

- Testing small sample rolls

- Printing at least 20-30 sheets

- Testing with actual production designs

- Performing a washing test after 24 hours

This practical approach helps avoid significant financial losses from large orders of the same batch.

How Koala Factory Responds to Real User Feedback

Koala Factory doesn't just rely on laboratory testing data; we continuously adjust the performance of our DTF Transfer film based on real user feedback from our distributors:

- Real-world user test data

- Production environment feedback

- Long-term stability reports

Improvement measures include:

- Tighter coating tolerance control

- Enhanced anti-static treatment

- Improved PET substrate stability

- Optimized release layer for different workflows

This user-oriented improvement cycle ensures that our film rolls perform reliably not only in theory but also in actual production.

Conclusion: What kind of DTF film rolls do users truly need?

All four types of users came to the same conclusion:

What users want is not the cheapest film, but long-lasting, consistent, and stable transfer results.

High-quality DTF film rolls should possess the following characteristics:

- Stable and consistent performance

- Reliable peeling

- Reduced waste

- Support for long-term continuous production

For users, the best film is the one that allows them to focus on their production, rather than troubleshooting problematic film.

Why does my DTF film not transfer completely?

Incomplete transfers are usually caused by uneven coating quality or poor ink absorption on the DTF film. If the film surface cannot anchor ink properly, even correct heat press settings will not solve the issue.

Is dtf powder adhesion always a powder quality problem?

Not always. Many users discover that inconsistent dtf powder adhesion comes from static imbalance or coating surface issues on the DTF film, not from the powder itself.

Why does my DTF film curl during heating?

Film curling is often related to low-quality PET base film or unstable tension control during film manufacturing. This issue becomes more visible during long production runs.

Which DTF film roll size is best for stable production?

For most users, 60cm DTF film rolls offer the best balance between efficiency, stability, and waste reduction. Smaller studios may prefer 30cm, while factories often use 100–120cm rolls.

How should I test a DTF film roll before placing a bulk order?

Users recommend running at least 20–30 real production prints using the same printer, ink, powder, and heat press settings, followed by a wash test after 24 hours.

Is a higher-priced DTF film always better?

Not necessarily. The best DTF film is the one that delivers consistent transfer results, stable peeling, and low defect rates over time—not simply the cheapest or most expensive option.