This article outlines how photo paper manufacturer Koala ensures steady supply for wholesalers through demand forecasting, production planning, flexible manufacturing, optimized warehousing and logistics. Their goal of digitally transforming operations increases efficiency and positions Koala as a reliable, dependable paper supplier for the long term.

Intro

●Commitment to Reliable Photo Paper Supply

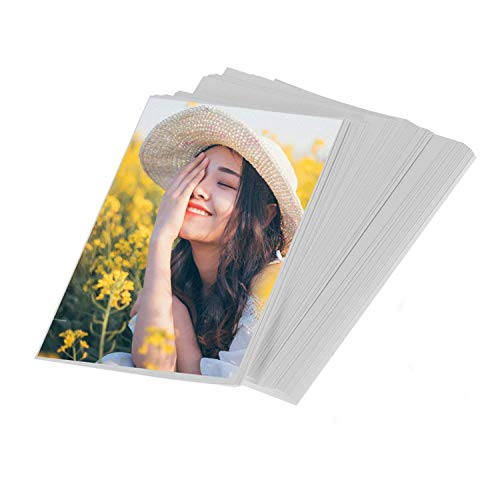

As a prestigious photo paper manufacturer with over a decade of experience in the industry, Koala® has provided premium inkjet papers to distributors and ensured steady supply. They take great pride in their repute for dependable distribution and being a reliable supplier. Maintaining an uninterrupted stock of top-quality papers is core to their brand commitment. Regardless of market demands, they strive to fulfill all wholesaler orders completely and minimize disruption to partners’ business.

Through continuous optimizing and innovations, robust infrastructure and production abilities have been developed to satisfy fluctuating needs efficiently. Advanced logistics and warehouse guarantee timely shipping of complete orders. Over ten years of strengthening relationships with hundreds of resellers through consistent delivery of premium products exhibits their dedication to wholesale partners. Partners’ endorsement of the sound supply chain underscores the company’s commitment to wholesalers.

●Discuss Strategies to Ensure Steady Wholesale Supply

This article discusses Koala®’s approaches to ensuring a stable and reliable wholesale supply of photo papers. As demand fluctuates throughout the year due to seasonal or market changes, maintaining adequate stock for wholesalers while controlling costs can be challenging. The article will outline Koala®’s demand forecasting process, adaptable production planning and optimized inventory management systems. These strategies work together smoothly to fulfill dealer needs. Case studies demonstrating initiatives such as their just-in-time manufacturing model and warehouse digitization project will be provided, showing how wholesale capabilities have been enhanced. By providing a better understanding of Koala®’s end-to-end supply chain operations, partners can be ensured of consistent paper sourcing. The goal is for all wholesalers to experience reliable and stable photo paper sourcing.

Understanding Wholesale Demand

●Photo Paper Wholesale Market Overview

The photo paper wholesale market supplies thousands of retail photo outlets, printer shops, online stores and independent resellers nationally. These businesses depend on consistent photo paper inventory to meet consumer and commercial printing needs. Industry figures show annual wholesale revenue reaches several billion dollars. Over the last five years, revenue has grown moderately as digital printing expands. However, monthly and seasonal demand fluctuates. Major dates like holidays, back to school and summer create peaks. Economic conditions also impact photo output levels. Wholesalers require steady supply to support these varying requirements faced by retailers.

●Fluctuating Dealer Needs and Importance of Reliability

Wholesalers aim to prevent out of stock situations to retain customers and sales. However, precisely forecasting demand is difficult due to changing consumer behavior and unpredictable market factors. They rely on dependable suppliers like Koala® to appropriately manage inventory levels through frequent replenishments. Dealers appreciate Koala®’s approach, avoiding overstock costs while ensuring fast-moving items remain available. Running out of high turnover products loses orders and loyalty. With production visibility, Koala® fulfills large post-holiday replenishments reliably for dealers. Adhering to scheduled delivery dates even during peak periods develops trust in Koala®’s long-term supply reliability.

Demand Forecasting and Production Planning

●Forecasting Wholesale Demand Process

Accurately anticipating wholesale volumes months in advance is critical for Koala®’s production planning. They have developed a sophisticated forecasting model integrating historical sales trends, planned marketing initiatives and external economic indicators. Koala® gathers monthly order data spanning 5 years from their ERP system. This extensive sales database is analyzed using specialized software identifying seasonal patterns and event-related demand fluctuations. Industry reports on latest photography and printing trends are also examined. Combining quantitative and qualitative insights helps reduce forecast errors each year. All contributes to a highly accurate 6-month demand projection for each SKU issued quarterly, narrowing production uncertainties for wholesalers.

●Planning Production ahead of Time based on Forecasts

Armed with the 6-month forecast, Koala®’s production team establishes a rolling capacity plan. Optimization algorithms determine the most cost-effective manufacturing schedule by considering facility capacity, packaging line throughputs, raw material lead times and scheduled maintenance to maximize equipment uptime. Close coordination with suppliers ensures consistent supply of papers, chemicals and packaging to support the production plan. Any risks to deadlines from supply issues are identified and addressed in advance. Monthly progress against the plan is monitored through their ERP dashboard. This visibility enables swift response if demand deviates from forecasts, such as implementing overtime shifts or third-party packaging contracts. The rigorous planning process aims to avoid unwarranted downtime and shortfalls.

Flexible Manufacturing Capabilities

●Adjusting Production Volume and Product Mix Flexibly

Digital printing technology allows Koala®’s manufacturing facilities to swiftly adjust output according to anticipated demand variations. Throughout the day, production supervisors monitor incoming wholesale orders in their ERP system. Leveraging this real-time sales data, they can dynamically modify manufacturing schedules up until the day of production. For example, if demand for a fast-moving item is unexpectedly 20% higher next quarter, factory lines can reconfigure within hours by altering settings to direct more capacity to that SKU. This agility permits optimizing equipment usage despite fluctuating needs.

●Maximizing Output within Capacity Constraints

Koala® utilizes flexible automation to avoid bottlenecks. Packaging lines can smoothly transition between product types, allowing monthly mix changes up to 30% without slowdowns. For example, carton erecting lines rapidly adjust from 2000 delivery boxes to 5000 bags per hour. Paper coating and slitting machinery also nimbly switch between sizes under automatic controls. These capabilities let supervisors handle spikes in SKUs without overtime. When inventory projections signal surplus, line adjustments are proactively implemented within capacity limits to balance production.

Standardized workflows mean mix changes during shifts incur minimal downtime. Digital processes expedite changeovers via recipe auto-generation from a centralized database. Equipment effectiveness monitoring sustains high asset productivity and flexibility despite hundreds of variants. This agile infrastructure underpins responsiveness to wholesalers’ needs.

Warehousing and Logistics Management

●Effective Inventory and Warehouse Management

Koala® operates three strategically located distribution centers across North America to ensure fast shipping. Advanced technologies such as RFID and voice-directed picking maximize space use and accuracy. Real-time inventory is tracked via automated counting. Optimized slotting places similar SKUs together for quicker put-away and order fulfillment. Dynamic replenishment rules maintained through their ERP system uphold appropriate safety stocks. An AS/RS consolidates pallets for dense storage, minimizing empty areas.

●Reliable Order Fulfilment Through Optimized Logistics Network

This integrated distribution network achieves over 98% same-day and next-day delivery accuracy. Multiple carriers collaborate through ongoing transit benchmarking and traffic congestion analysis. A transportation management system generates optimized routes factoring vehicle capacity, addresses and real-time traffic to consolidate LTL shipments. Multi-drop deliveries are expertly sequenced for efficiency. Carriers can also swiftly accommodate expedited orders via air freight programs.

Wholesalers value visibility into production updates and shipment tracking extended across the centralized omnichannel system. These capabilities deliver best-in-class fill rates and service levels consistently. Therefore Koala remains the reliable photo paper supplier wholesalers have come to depend on.

Continuous Improvement

Continuous improvement is ingrained in Koala®’s culture. They meticulously evaluate processes to enhance responsiveness and optimize costs. For example, after benchmarking distribution workflows, a new WMS was adopted utilizing configurable rules to streamline inventory receiving and placement. This accelerated DC throughput 15%. Industrial printers also replaced manual shelf labeling, cutting time in half. Their R&D team creates new formulation methods to reduce paper waste during coating tests. Koala® consistently seeks process enhancements through analysis and benchmarking across facilities to sustain reliable wholesale support.

Benefits for Partners

Through optimized operations ensuring stable supply, Koala provides reliability for wholesale partners. With reliable 6-month visibility into production schedules, unexpected price increases from shortages are avoided. Long-term output commitments also facilitate negotiated pricing with minimal quarterly changes. Additionally, Koala®’s efficient infrastructure controls costs so savings are passed along. Thus wholesalers can anticipate consistent photo paper expenses and profit margins over time thanks to Koala®’s optimized operations.

Conclusion

Over the past decade, Koala® has worked to solidify its reputation as a symbol of reliability for wholesalers in the photo industry. They understand an uninterrupted paper supply is essential for distributors to seamlessly run their businesses. By sustainably strengthening planning, manufacturing and logistics through ongoing digital transformation, Koala® aims to justify wholesalers’ long-standing trust. Whether accurately forecasting demand months in advance, delivering orders on schedule or providing full visibility, Koala® is committed to serving as the dependable backbone for global photo retailers.

Looking ahead, Koala® will continue advancing to raise the bar for wholesale support. Expanded R&D into automation and new coating can boost response to custom requests. Collaborative warehousing with key distributors may further consolidate transportation. Leveraging IoT sensors and AI maintenance can preventively optimize equipment uptime. Emerging partnership models may weather uncertainties through data sharing.

In conclusion, Koala®’s focus on putting wholesalers first through reliable service remains unchanged. By proactively navigating supply chain frontiers, Koala® aims to cement its position as photo distributors’ most dependable provider. Their growing engineering team dedicates to excelling through continuous upgrades leveraging innovations. With ongoing support and insights from partners, Koala® is committed to ensuring worry-free operations across the imaging industry value chain.